Impactfactor.org

Available online on www.ijddt.com

International Journal of Drug Delivery Technology 2014; 4(4); 58-66

Microsponges: An Overview

*Hamid Hussain, Divya Juyal, Archana Dhyani

Himalayan Institute of Pharmacy and Research Rajawali Dehradun, India

Available Online: 29th September 2014

ABSTRACT

Microsponge and Nanosponge delivery System was originally developed for topical delivery of drugs can also be used for

controlled oral delivery of drugs using water soluble and bioerodible polymers. Microsponge delivery system (MDS) can

entrap wide range of drugs and then release them onto the skin over a time by difussion mechanism to the skin. It is a

unique technology for the controlled release of topical agents and consists of nano or micro porous beads loaded with active

agent and also use for oral delivery of drugs using bioerodible polymers.

Keywords: Microsponge drelivery system (MDS), Nanosponge. Bioerodible.

response to triggers including rubbing, pH, friction,

Microparticles and nanoparticles have been increasingly

moisture and ambient skin temperature[5].

investigated to achieve targeted and sustained release of

Advantages of microsponges:

drugs [1] and among this microsponge is one of the recent

Microsponges are biologically safe and offer unique

and an innovative noval approach to deliver a drug in a

advantage of programmable release.

controlled way.

They offer entrapment of numerous ingredients and is

They are tiny, sponge like spherical particles that consist

believed to contribute elegance and enhanced

of a myriad of interconnecting voids within a non-

collapsible structure with a

large porous surface

Have the capacity to adsorb or load a high degree of

Microsponge delivery systems (MDS) that can precisely

active materials into the particle or unto its surface.

control the release rates or target drugs to a specific body

Microsponges are stable over a ph range of 1-11 and

site have an enormous impact on the health care system.

upto temperature of 130 ºc

The microsponge drug delivery technology is widely

They are self sterilizing as average pore size is 0.25 µm

applicable to the dermatological drug delivery products.

where bacteria cannot penetrate.

But MDS also expands its application in oral drug delivery,

Microsponges are capable of absorbing skin secretions

bone and tissue engineering, in Detecting the diseases and

so reducing the oiliness of the skin upto 6 times of its

in RNAi silencing. New classes of pharmaceuticals,

biopharmaceuticals (peptides, proteins and DNA-based

With size 10-25 microns in diameter it is capable of

therapeutics) are fueling the rapid evolution of drug

delivery technology. Thus MDS is a very emerging field

which is needed to be explored [2]

. Microsponges are

The drug releases in microsponges y the external stimuli

porous, polymeric microspheres that are mostly used for

like ph, temperature, and rubbing.

prolonged topical

Microsponges have several advantages over topical

designed to deliver a pharmaceutically active ingredient

preparations in being nin-allergic, non-toxic, non-irritant

efficiently at minimum dose and also to enhance stability,

and non-mutagenic.

reduce side effects, and modify drug release profiles [3].

it is a polymeric microspheres that acquire the flexibility

Microsponges are all ways stable i.e, thermal, physical

to entrap a wide variety of active ingredients such as

and chemical [6].

emollients, fragrances, sunscreens, essential oils, anti-

These are compatible with the majority of vehicles and

infective, anti-fungal and anti-inflammatory agents etc and

are used as a topical carrier system[4]. Resembling a true

These systems have higher payload up to 50 to 60% [5].

sponge, each microsphere consists of an innumerable of

Advantages of Microsponges over Other Formulations

interconnecting voids within a non-collapsible structure

Microsponges have several other advantages over other

with a large porous surface. It is a unique technology for

preparations available in the market. Comparison between

the controlled release of topical agents which consists of

some of them are given below as such;

microporous beads normally 10-25 microns in diameter,

Advantages over conventional formulations: Conventional

loaded with active ingredients that is subsequently releases

formulations of topical drugs are intended to work on the

them onto the skin over a time in a controlled manner or in

*Author for correspondence: E-mail: [email protected]

Hamid Hussain et al. / Microsponges: An Overview…

outer layers of the skin. Such products release their active

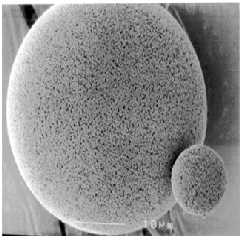

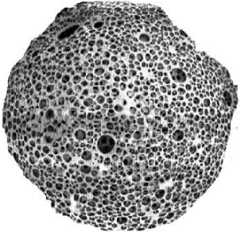

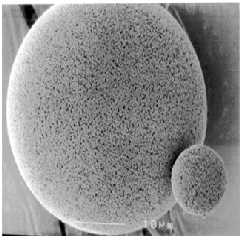

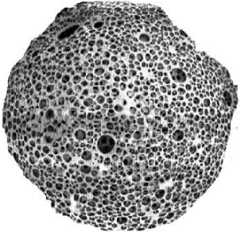

Fig. 1: View of microsponge

Fig. 2: Highly porous nature of a Microsponge

ingredients upon application, producing a highly

It should exhibit complete miscibility in monomer or

concentrated layer of active ingredient that is rapidly

have the ability to be miscible using the least amount of

adsorbed. When compared to the conventional system.

a water immiscible solvent.

Microsponge system can prevent excessive accumulation

Must be inert to monomers and do not increase the

of ingredient within the epidermis and the dermis.

viscosity of the preparation during formulation.

Potentially, the MDDS can reduce significantly the

It should be water immiscible or almost slightly soluble.

irritation of effective drugs without reducing their efficacy.

The solubility of active ingredients in the vehicle should

Advantages over microencapsulations and liposomes: The

be minimum; otherwise the microsponge will be

MDS has advantages over other technologies like

diminished by the vehicle before application.

microencapsulations and liposomes. Microcapsules cannot

It should maintain (preserve) the spherical structure of

usually control the release rate of actives. Once the wall is

ruptured, the actives contained within microcapsules will

It should be stable in polymerization conditions.

be released.

Only 10 to 12% w/w microsponge can be incorporated

Liposomes suffer

lower payload, difficult

into the vehicle to eliminate cosmetic delinquent.

formulation, limited chemical stability and microbial

Payload and polymer design of the microsponges for the

instability, while microsponges system in contrast to the

active must be adjusted to obtain the desired release rate

above system has several advantages like stable over a ph

of a given period of time. [9].

range of 1-11 and upto temperature of 130 ºc, stable

Methods of preparation for microsponges: Initially, drug

thermally, physicaly and chemically, have higher payload

loading in microsponges is mainly take place in two ways

up to 50 to 60%, have average pore size is 0.25 µm whwre

depending upon the physicochemical properties of drug to

bacteria cannot penetrate[7].

be loaded. If the drug is typically an inert non-polar

Advantages over ointments:

Ointments are often

material which will generate the porous structure then, it is

aesthetically unappealing, greasiness; stickiness etc. That

known as porogen. A Porogen drug neither hinders the

often results into lack of patient compliance. These

polymerization process nor become activated by it and also

vehicles require high concentrations of active agents for

it is stable to free radicals is entrapped with one-step

effective therapy because of their low efficiency of

delivery system, resulting into irritation and allergic

Microsponges are suitably prepared by the following

reactions in significant users. Other drawbacks of topical

formulations are uncontrolled evaporation of active

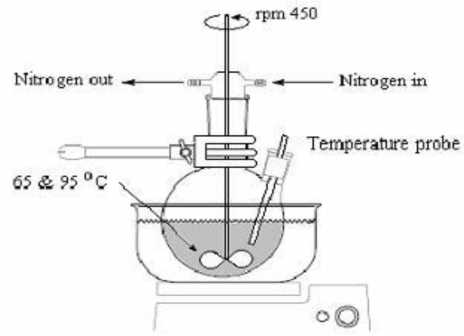

Liquid-liquid suspension polymerization: The porous

ingredient, unpleasant odor and potential incompatibility

microspheres are prepared by suspension polymerization

of drugs with the vehicles, when microsponge system

method in liquid-liquid systems. In their preparation, the

maximize amount of time that an active ingredient is

monomers are first dissolved along with active ingredients

present either on skin surface or within the epidermis,

in a suitable solvent solution of monomer and are then

while minimizing its transdermal penetration into the

dispersed in the aqueous phase, which consist of additives

(surfactant, suspend-ing agents, etc. to aid in formation of

Characters of Drugs to be entrapped in the Microsponges:

suspension). The polymerization is then initiated by adding

There are certain requirements that should be fulfilled (or

catalyst or by increasing temperature or irradiation. The

considered) when active ingredients are entrapped into

various steps in the preparation of microsponges are

summarized as.

Selection of monomer or combination of mono-mers.

IJDDT, October-December 2014, 4(4), 58-66

Hamid Hussain et al. / Microsponges: An Overview…

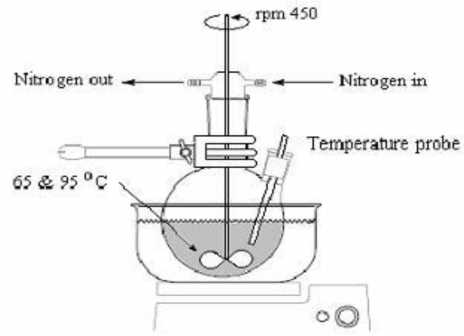

Fig 3: Instrument set up for suspension polymerization technique

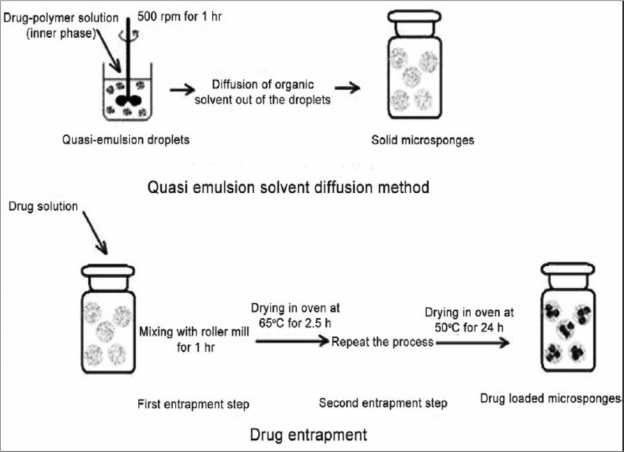

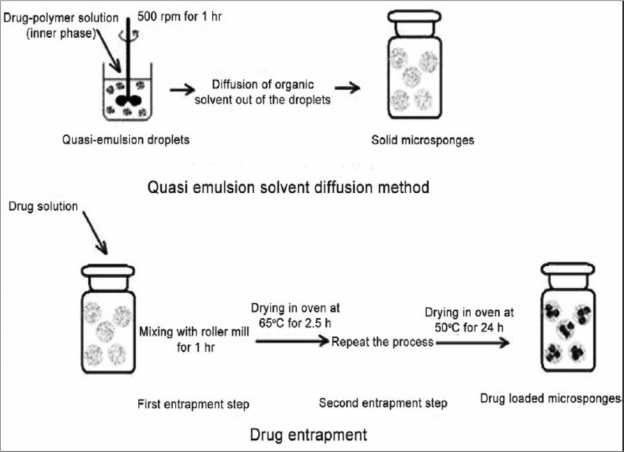

Fig 4: Quasi-emulsion solvent diffusion method set up.

Formation of chain monomers as polymerization begins.

Binding of bunches to form microsponges. [10]

Formation of ladders as a result of cross linking between

Quasi-emulsion solvent diffusion method: (Top down

chain monomers.

approach): This is top-down approach starting with

Folding of monomer ladder to form spherical particles.

preformed polymer. This process involved formation of

Agglomeration of microspheres, which give rise to

quasi-emulsion of two different phases i.e. internal phase

formation of bunches of microspheres.

IJDDT, October-December 2014, 4(4), 58-66

Hamid Hussain et al. / Microsponges: An Overview…

and external phase similar to emulsions. The internal phase

Determination of true density: The true density of

of drug--polymer solution made in a volatile solvent like

Microsponges can be measured using an ultra-pycnometer

ethanol or acetone or dichloromethane was added to

under helium gas and is calculated from a mean of repeated

external phase comprising the aqueous polyvinyl alcohol

(PVA) solution with vigorous stirring. Triethylcitrate

Pore structure: Porosity parameters of microsponges are

(TEC), which was added at an adequate amount in order to

essential in monitoring the intensity and the duration of

facilitate plasticity. Stirring lead to the formation of

active ingredient effect. Average pore diameters, shape

discrete emulsion globules called quasi-emulsion globules.

and morphology of the pores can be determined by using

Solvent was then extracted out from these globules to form

mercury intrusion porosimetry technique. The effect of

pore diameter and volume on the rate of drug release from

Following sufficient stirring, the mixture was then filtered

microsponges can also be studied using the same

to separate the microsponges. The microsponges were then

technique. [17].

dried in an air heated oven. Conceptually, the finely

Compatibility studies: The drug-excipient compatibility

dispersed droplets of the polymeric solution of the

studies are carried out in order to ensure that there is no

drug(dispersed phase) get solidified in aqueous phase via

inadvertent reaction between the two when formulated into

counter diffusion of organic solvent and water out of and

a dosage form. These studies are commonly carried out by

into the droplets. The diffused aqueous phase within the

recording the differential scanning calorimetry (DSC) of

droplets decreased the drug and polymer solubility

both the chemicals viz., API and excipient individually and

resulting in the co-precipitation of both the components

also together and checking for any addition or deletion of

and continued diffusion of the organic phase results in

any peaks or troughs. For DSC approximately 5 mg

further solidification, producing matrix-type porous

samples can be accurately weighed into aluminium pans

and sealed and can be run at a heating rate of 15oC/min

suspension polymerization method, this method offered

over a temperature range 25–430oC in atmosphere of

the advantage of less exposure of the drug to the ambient

nitrogen. [18,19].

conditions, low solvent residues in the product because the

spectroscopy can also reveal the

solvent get extracted out due to its solubility in aqueous

incompatibilities

media or due to its volatile nature. [11,12,13]

Compatibility of drug with reaction adjuncts can also be

Evaluation Parameters

studied by thin layer chromatography (TLC) and FT-IR

Particle size and size distribution: Particle size and size

[35]Effect of polymerization on crystallinity of the drug

distribution are evaluated using either an optical

can be studied by powder X-ray diffraction (XRD) and

microscope or an electron microscope. This is an

Differential Scanning Colorimetry (DSC). [20].

extremely crucial step, as the size of the particles greatly

Polymer/ Monomer composition: Factors such as particle

affects the texture of the formulation and its stability. Free-

size, drug loading, and polymer composition govern the

flowing powders with fine aesthetic attributes are possible

drug release from Microsponges. Polymer composition of

to obtain by controlling the size of particles during

the Microsponges Drug Delivery system can affect

polymerization. Particle size analysis of loaded and

partition coefficient of the entrapped drug between the

unloaded Microsponges can be performed by laser light

vehicle and the Microsponges system and hence have

diffractometry or any other suitable method. The values

direct influence on the release rate of entrapped drug.

(d50) can be expressed for all formulations as mean size

Release of drug from Microsponge systems of different

range. Cumulative percentage drug release from

polymer compositions can be studied by plotting

Microsponges of different particle size will be plotted

cumulative % drug release against time. Release rate and

against time to study effect of particle size on drug release.

total amount of drug released from the system composed

of methyl methacrylate/ ethylene glycol dimethacrylate is

Morphology and Surface topography of SPM: For

slower than styrene/divinyl benzene system. Selection of

morphology and surface topography, various techniques

monomer is dictated both by characteristics of active

have been used like photon correlation spectroscopy

ingredient ultimately to be entrapped and by the vehicle

(PCS), Scanning electron microscopy (SEM), transmission

into which it will be dispersed. Polymers with varying

electron microscopy (TEM) etc. SEM is used widely for

electrical charges or degrees of hydrophobicity or

which prepared Microsponges are coated with gold–

lipophilicity may be prepared to provide flexibility in the

palladium under an argon atmosphere at room temperature

release of active ingredients. Various monomer

and then the surface morphology of the Microsponges is

combinations will be screened for their suitability with the

studied. [15].

drugs by studying their drug release profile. [21].

Determination of loading efficiency and production yield:

Resiliency (viscoelastic properties) of

The loading efficiency (%) of the Microsponges can be

Microsponges can be modified to produce beadlets that is

calculated according to the following equation:

softer or firmer according to the needs of the final

The production yield of the microparticles can be

formulation. Increased cross-linking tends to slow down

determined by calculating accurately the initial weight of

the rate of release. Hence resiliency of Microsponges is

the raw materials and the last weight of the SPM obtained.

studied and optimized as per the requirement by

considering release as a function of crosslinking with time

IJDDT, October-December 2014, 4(4), 58-66

Hamid Hussain et al. / Microsponges: An Overview…

Table 1: Marketed formulations of microsponges[38,39]Product name

Dermik Laboratories, Inc.

Carac Cream contains 0.5% fluorouracil; with 0.35% being

Berwyn , PA 19312 USA

incorporated into a patented porous microsphere consisted ofmethyl methacrylate / glycol dimethacrylate cross-polymer anddimethicone. Carac is a once-a-day topical prescription productfor the treatment of actinic keratosis (AK) that is characterizedby common pre-cancerous skin condition caused byoverexposure to the sun.

Salicylic Peel 20

Retin-A-Micro contains 0.1% and 0.04% tretinoin entrapped into

a patented porous microsphere consisted of methyl methacrylate/glycol dimethacrylate cross-polymer to enable inclusion of theactive ingredient, tretinoin, in an aqueous gel. This formulationis used for the topical treatment of acne vulgaris.

Salicylic acid 20%, microsponge technology has excellentexfoliation and used for stimulation of the skin for more resistantskin types or for faster results. It will considerably improvepigmentation, fine lines and acne concerns. Salicylic acid moveseasily through the pores, clearing them out while reducinginflammation. This treatment effectively combats acne leavingan amazingly smooth and clear complexion.

Lightweight cream with a retinol (Vitamin A) in MDS, dual-

system delivers both immediate and time released wrinkle-

fighting action. Clearly diminishes appearance of fine lines,

wrinkles & skin discolorations associated with aging.

Retin-A-Micro contains 0.1% and 0.04% tretinoin entrapped into

a patented porous microsphere consisted of methyl methacrylate/glycol dimethacrylate cross-polymer to enableinclusion of the active ingredient, tretinoin, in an aqueous gel.

This formulation is used for the topical treatment of acnevulgaris.

The MicroPeel ® Plus procedure stimulates cell turnover through

the application of salicylic acid in the form of microcrystals usingMicrosponge® technology. These microcrystals target the exactareas on the skin that need improvement. The MicroPeel Plusaggressively outperforms other superficial chemical peels byfreeing the skin of all dead cells while doing no damage to theskin.

A night time treatment cream with Microsponge technology

using a stabilized formula of pure retinol, Vitamin A. Continued

use of Retinol 15 will result in the visible diminishment of finelines and wrinkles, a noticeable improvement in the skindiscolorations due to aging, and enhanced skin smoothness.

SDR Pharmaceuticals, Inc.,

Lactrex™ 12% Moisturizing Cream contains 12% lactic acid as

Andover , NJ , U.S.A. 07821

the neutral ammonium salt, ammonium lactate. Microsponge®

technology has been included for easy application and longlasting moisturization. Lactrex™ also contains water andglycerin, a natural humectant to soften and help moisturize drys,flaky, cracked skin.

The Microsponge® system uses microscopic reservoirs thatentrap hydroquinone and retinol.

The microsponges release these ingredients into the skingradually throughout the day. This provides the skin withcontinuous exposure to hydroquinone and retinol over time,which may minimize skin irritation. EpiQuin Micro is aprescription moisturizing fading cream that reducesthe impact of these conditions known as melasma, postinflammatory hyper pigmentation or solar lentigines. Also helpin Age spots, Sun spots and Facial discoloration.

IJDDT, October-December 2014, 4(4), 58-66

Hamid Hussain et al. / Microsponges: An Overview…

Table 1: Marketed formulations of microsponges[38,39]Product name

Oil free matte block

This invisible oil-free sunscreen shields the skin from damaging

UV sun rays while controlling oil production, giving you ahealthy matte finish. Formulated with microsponge technology,Oil free matter block absorbs oil and preventing shine withoutany powdery residue.

Sportscream RS and

Embil Pharmaceutical Co.

Topical analgesic-anti-inflammatory and counterirritant actives

in a microsponge® deliverysystem (MDS) for the management of musculoskeletalconditions.

Oil Control Lotion

Fountain Cosmetics

A feature-light lotion with technically advanced microspongesthat absorb oil on the skin's surface during the day, for a mattefinish. Eliminate shine for hours with this feature-weightlotion, formulated with oil-absorbing Microsponge technology.

The naturally- antibiotic Skin Response Complex soothesinflammation and tightness to promote healing. Acne-Prone,oily skin conditions.

Kinetics of release: To determine the drug release

intervals and analyzed using suitable method of assay

mechanism and to compare the release profile differences

(Embil and Nacht, 1996; Jelvehgari et al., 2006). To

among microsponges, the drug released amount versus

determine the drug release kinetics and investigate its

time was used. The release data were analysed with the

mechanism from microsponges, the release data are fitted

following mathematical models:

to different kinetic models. The kinetic models used are;

Q= k1tn or log Q= log k1 + n log t ………………Equation

first order, zero order, Higuchi and Korsmeyer- Peppas

models (Higuchi, 1963; Wagner, 1969; Korsmeyer et al.,

Where Q is the amount of the released at time (h), n is a

1983; Peppas, 1985). The goodness of fit was evaluated

diffusion exponent which indicates the release mechanism,

using the determination coefficient (R2) values. [24]

and k1 is a constant characteristic of the drug–polymer

Safety Considerations

interaction. From the slope and intercept of the plot of log

Safety studies of microsponges can be confirmed by;

Q versus log t, kinetic parameters n and k1 were calculated

Allergenicity in guinea pigs

For comparison purposes, the data was also subjected to

Eye irritation studies in rabbits

Equation (2), which may be considered a simple, Higuchi

Mutagenicity in bacteria

type equation.

Oral toxicity studies in rats.

Q = k2t0.5 +C ………………… Equation (2)

Skin irritation studies in rabbits. [25,26,27]

Equation (2), for release data dependent on the square root

Applications of Microsponge Systems: Microsponge

of time, would give a straight line

delivery systems are used to enhance the safety,

release profile, with k2 presented as a root time dissolution

effectiveness and aesthetic quality of topical prescription,

rate constant and C as a constant. [23].

over-the-counter and personal care products. Products

under development or in the market place utilize the

In vitro release studies, release kinetics and mechanism:

Topical Microsponge systems in three primary ways:

In vitro release studies can be performed using United

As reservoirs releasing active ingredients over an

States Pharmacopeial (USP) dissolution apparatus

extended period of time,

equipped with a modified basket consisted of 5 μm

As receptacles for absorbing undesirable substances,

stainless steel mesh at 37°C. The release medium is

such as excess skin oils, or

selected according to the type of formulation that is, topical

As closed containers holding ingredients away from the

or oral, while considering solubility of active ingredients

skin for superficial action.

to ensure sink conditions. Sample aliquots are withdrawn

Releasing of active ingredients from conventional topical

from the medium and analyzed by suitable analytical

formulations over an extended period of time is quite

method at regular intervals of time. The drug release from

topical preparations (for example, creams, lotions and

Cosmetics and skin care preparations are intended to work

emulgels) containing microsponges can be carried out

only on the outer layers of the skin. The typical active

using Franz diffusion cells. Dialysis membrane is fitted

ingredient in conventional products is present in a

into place between the two chambers of the cell. A

relatively high concentration and, when applied to the skin,

predetermined amount of formulation is

may be rapidly absorbed. The common result is over-

mounted on the donor side of Franz cell. The receptor

medication, followed by a period of under-medication until

medium is continuously stirred at and thermostated with a

the next application. Rashes and more serious side effects

circulating jacket. Samples are withdrawn at different time

can occur when the active ingredients rapidly penetrate

below the skin's surface. Microsponge technology is

IJDDT, October-December 2014, 4(4), 58-66

Hamid Hussain et al. / Microsponges: An Overview…

designed to allow a prolonged rate of release of the active

microsponges were prepared by the direct compression

ingredients, thereby offering potential reduction in the side

method. Results indicated that compressibility was much

effects while maintaining the therapeutic efficacy. [28].

improved in the physical mixture of the drug and polymer;

Microsponge for topical delivery: The Microsponge

due to the plastic deformation of the sponge-like

systems are based on microscopic, polymer-based

microsponge structure, producing mechanically strong

microspheres that can bind, suspend or entrap a wide

tablets. Colon-specific, controlled delivery of flurbiprofen

variety of substances and then be incorporated into a

was conducted by using a commercial Microsponge®

formulated product, such as a gel, cream, liquid or powder.

5640 system. In vitro studies exhibited that compression-

A single Microsponge is as tiny as a particle of talcum

coated colon-specific tablet formulations started to release

powder, measuring less than one-thousandth of an inch in

the drug at the eighth hour, corresponding to the proximal

diameter. Like a true sponge, each microsphere consists of

colon arrival time, due to addition of the enzyme,

a myriad of interconnecting voids within a non-collapsible

following a modified release pattern, while the drug

structure that can accept a wide variety of substances. The

release from the colon-specific formulations prepared by

outer surface is typically porous, allowing the controlled

pore plugging the microsponges showed an increase at the

flow of substances into and out of the sphere.

eighth hour, which was the point of time when the enzyme

Several primary characteristics, or parameters, of the

addition was made. [33,34].

Microsponge system can be defined during the production

Microsponge for Bone and Tissue Engineering: Bone-

phase to obtain spheres that are tailored to specific product

substitute compounds were obtained by mixing pre

applications and vehicle compatibility. Microsponge

polymerized powders of polymethylmethacrylate and

systems are made of biologically inert polymers. Extensive

liquid methylmethacrylate monomer with two aqueous

safety studies have demonstrated that the polymers are

dispersions of tricalcium phosphate grains and calcium

non-irritating, nonmutagenic, non-allergenic, non-toxic

deficient hydroxyapatite powders. The final composites

and non-biodegradable. As a result, the human body

appeared to be porous and acted as microsponges. Basic

cannot convert them into other substances or break them

fibroblast growth factor (bFGF) incorporated in a collagen

down. Although they are microscopic in size, these

sponge sheetwas sustained released in the mouse sub-cutis

systems are too large to pass through the stratum corneum

according to the biodegradation of the sponge matrix, and

when incorporated into topical products [29]. Benzoyl

exhibited local angiogenic activity in a dose-dependent

peroxide (BPO) is commonly used in topical formulations

manner. The injection of collagen microsponges

for the treatment of acne,with skin irritation as a common

incorporating bFGF induced a significant increase in the

side effect. It has been shown that controlled release of

blood flow, in the murine ischemic hind limb, which could

BPOfrom a delivery system to the skin could reduce the

never have been attained by the bolus injection of bFGF.

side effect while reducing percutaneous absorption.

These results suggest the significance and therapeutic

Therefore, microsponge delivery of Benzoyl peroxide was

utility of the type I collagen as a reservoir of bFGF. [35,36]

developed using an emulsion solvent diffusion method by

Future Prospects: Microsponge drug delivery system holds

adding an organic internal phase containing benzoyl

a promising opportunity in various pharmaceutical

peroxide, ethyl cellulose and dichloromethane into a

applications in the upcoming future as it has unique

stirred aqueous phase containing polyvinyl alcohol and by

properties like enhanced produc

suspension polymerization of styrene and divinyl benzene

elegancy, extended release, improved drug release profile,

.The prepared microsponges were dispersed in gel base

reduced irritation, improved physical, chemical and

and microsponge gels are evaluated for anti-bacterial and

thermal stability which makes it flexible to develop novel

skin irritancy. The entrapped system released the drug at

product forms. The real challenge in future is the

slower rate than the system containing free BPO. Topical

development of the delivery system for the oral peptide

delivery system with reduced irritancy was successfully

delivery by varying ratio of polymers. The use of

bioerodible and biodegradable polymers for the drug

Microsponge for oral delivery: In oral applications, the

delivery is enabling it for the safe delivery of the active

microsponge system has been shown to increase the rate of

material. As these porous systems have also been studied

solubilization of poorly water-soluble drugs by entrapping

for the drug delivery through pulmonary route which

such drugs in the microsponge system's pores. As these

shows that these system can show effective drug release

pores are very small, the drug is in effect reduced to

even in the scarce of the dissolution fluid thus colon is an

microscopic particles and the significant increase in the

effective site for targeting for drug release. These carriers

surface area thus greatly increases the rate of

also require to be developed for alternative drug

solubilization. Controlled oral delivery of ibuprofen

administration routes like parenteral and pulmonary route.

microsponges is achieved with an acrylic

These particles can also be used as the cell culture media

polymer, Eudragit RS, by changing their intraparticle

thus can also be employed for stem cell culture and cellular

chlorpheniramine

regenaration in the body. Due to their elegance, these

microsponges, is prepared by the dry impact blending

carrier systems have also found their application in

method, for oral drug delivery. Controlled oral delivery of

cosmetics. These developments enabled researchers to

Ketoprofen prepared by quasi-emulsion solvent diffusion

utilize them variably. These novelties in formulation also

method with Eudragit RS 100 and afterwards tablets of

open new ways for drug delivery. [37]

IJDDT, October-December 2014, 4(4), 58-66

Hamid Hussain et al. / Microsponges: An Overview…

characterization and release studies. International

MDS has become highly competitive and rapidly evolving

Journal of Pharmaceutics (2006)124-132.

technology and more and more research are carrying out to

12. Kawashima Y, Niwa T, Takeuchi H, Hino T, Ito Y.

optimize cost-effectiveness and efficacy of the therapy.It

Control of Prolonged Drug Release and Compression

is a unique technology for the controlled release of topical

Properties of Ibuprofen Microsponges with Acrylic

agents and consists of microporous beads loaded with

active agent and also use for oral as well as

Intraparticle Porosity. Chemical and pharmaceutical

biopharmaceutical drug delivery. Microsponge delivery

bulletin. (1992) 196-201

systems that can precisely control the release rates or target

13. Comoglu T, Gonul N, Baykara T. Preparation and in

drugs to a specific body site have a vast impact on the

vitro evaluation of modified release ketoprofen

health care system. A microsponge delivery system can

microsponges. ll Farmaco. (2003) 101-6.

release its active ingredient on a time mode and also in

14. Martin A., Swarbrick J., Cammarrata A. In:Physical

response to other stimuli. Therefore, microsponge has got

Pharmacy- Physical Chemical Principles in Pharma-

a lot of potential and is a very emerging field which is

ceutical Sciences. 3rd Ed. (1991) 527

needed to be explored. Microsponges constitute a

significant part by virtue of their small size and efficient

characterization

thermoresponsive

Pharmaceutics. (1995) 237-242.

16. Kilicarslan M, Baykara T. The effect of the

De-Jalon EG, Blanco-Prieto MJ, Ygartua P, Santoyo

drug/polymer ratio on the properties of Verapamil

HCl loaded microspheres. Int. J. Pharm. (2003) 99–

microparticles: quantification of the drug in porcine

skin layers. J Control Release. (2001) 191–7.

17. Hibah Aldawsari1 and Shaimaa M. Badr-Eldin.

Bhimavarapu, Ramesetti RamaDevi,

Microsponges as promising vehicle for drug delivery

and targeting: Preparation, characterization and

,Sowjanya Paparaju. Microsponges: As a Novel

Applications. AJPP (8 May, 2013) 876

Imperative for Drug Delivery System. RJPT: (August

18. Jones D.S., Pearce K.J. Investigation of the effects of

some process variables on microencapsulation of

Orlu M, Cevher E, Araman A. Design and evaluation

propranolol HCl by solvent evaporation method. Int J.

of colon specific drug delivery system containing

Pharm (1995) 99-205.

flubiprofen microsponges. Int J Pharm. (2006)

19. Kawashima Y, Niwa T, Takeuchi H, Hino T, Itoh Y,

Furuyama S. Characterization of polymorphs of

Embil K, Nacht S, The microsponge delivery system

tranilast anhydrate and tranilast monohydrate when

(MDS): A topical delivery system with reduced

crystallized by two

solvent change spherical

crystallization techniques. J. Pharm. Sci. (1991) 472-

Microencapsul, 13, (1996) 575-588.

20. Ford J.L., Timmins P. Pharmaceutical Thermal

Techniques and Applications.

Arunabha.reCENT ADVANCES IN MIROSPONGES DRUG

Horwood Ltd.: Chichester .(1989)

DELIVERY SYSTEM. , IJPSRR: (May – June 2011) 13-

Microspheres for Controlled Drug Delivery. Biol.

Gangadharappa, H.V; vishal Gupta N.; Chandra

Pharm. Bull .(2004) 1717- 1724.

Prasad M., Sara; Shivakumar, H.G. Current trends in

22. Peppas N.A., Analysis of Fickian and non-Fickian

Microsponge drug delivery system.

drug release from polymers. Pharm. Acta Helv. (1985)

N.H palookar,A.S kulkarni, D.J Ingale and R.A patil.

Microsponges as innovative drug delivery system.

23. Hibah Aldawsari1 and Shaimaa M. Badr-Eldin.

IJPSN volume 5. issue 1. (April-june 2012) 1600-

Microsponges as promising vehicle for drug delivery

and targeting: Preparation, characterization and

Saroj Kumar Pradhan: microsponges as the versatile

Applications. AJPP (8 May, 2013) 877

tool for drug delivery system

24. Sato T., Kanke M., Schroeder G., Deluca P. Porous

Hibah Aldawsari1 and Shaimaa M. Badr-Eldin.

biodegradable microspheres for controlled drug

Microsponges as promising vehicle for drug delivery

delivery. Assessment of processing conditions and

and targeting: Preparation, characterization and

solvent removal techniques. Pharm Res. (1988) 21-

Applications. AJPP ( 2013) 875

10. Viral Shaha, Hitesh Jain1, Jethva Krishna1, Pramit

25. Kilicarslan M, Baykara T. The effect of the

Patel. Microsponge drug delivery: A Review. IJRPS

drug/polymer ratio on the properties of Verapamil

HCl loaded microspheres. Int. J. Pharm. (2003) 99–

11. Jelvehgari M, Siahi-Shadbad MR, Azarmi S, Gary P,

Martin, Nokhodchi A: The microsponge delivery

IJDDT, October-December 2014, 4(4), 58-66

Hamid Hussain et al. / Microsponges: An Overview…

26. Draize J.H., Woodard G., Calvery H.O. Methods for

Preparation and characterization. Tropical Journal of

the study of irritation and toxicity of substance es

Pharmaceutical Research, (2010) 67-72

applied topically to the Skin and Mucous Membranes.

33. Mine Orlu, Erdal Cevher, Ahmet Araman Design and

J Pharmacol ExpTher .(1944) 377-389.

evaluation of colon specific drug delivery system

27. Saraf A., Dasani A.,Pathan H., Microsponge drug

containing flurbiprofen microsponges, International

delivery system as an innovation in Cosmetic world A

Journal of Pharmaceutics, (2006) 103–117.

Review. Asian Journal of Pharmaceutical Education

34. Shaheen S Z, Bolla K, Vasu K & Singara C M A.

and Research, (2012) 2278 – 7496

Antimicrobial activity of the fruit extracts of Coccinia

28. Patel G., Patel J., Use of a Microsponge in Drug

indica. African Journal of Biotechnology Vol. 8(24)

Delivery Systems, Pharmaceutical processing, (2008)

35. Park W H, Lee S J and Moon H I. Antimalarial

29. D'souza JI. In-vitro Antibacterial and Skin Irritation

Activity of a New Stilbene Glycoside

Studies of Microsponges of Benzoyl Peroxide. Indian

Parthenocissus tricuspidata in Mice. Antimicrobial

Drugs. (2001) 23.

Agents and Chemotherapy. 52(9) (2008): 3451–3453.

30. Wester R., Patel R., Natch S., Leyden J., Melendres J.,

36. Srivastava R, Pathak K. Microsponges: a futuristic

Maibach H., Controlled release of benzoyl peroxide

approach for oral drug delivery. Expert Opin. Drug

from a porous microsphere polymeric system can

Deliv., (2012) 863-878.

reduce topical irritancy, J. Am. Acad. Derm., (1991)

37. Embil VP, OTC external analgesic cream/topical

analgesic anti-inflammatory, counterirritant utilizing

31. John I. D'souza, Jagdish K. Saboji, Suresh G. Killedar,

the microsponge delivery system (MDS) for

Harinath N. More "Design and Evaluation of Benzoyl

controlled release of actives, UK Patent 01010586,

Peroxide Microsponges to Enhance Therapeutic

Treatment", Accepted for

38. Grimee PE, Meraz M, A new microentrapped 4%

presentation in 20th FAPA Congress, Bangkok ,

Thailand ,( Nov30- Dec 3, 2004

hyperpigmentation, 60th Annual meeting of American

32. Jain V., Singh R., Dicyclomine-loaded eudragit based

Academy of Dermatology. (2002) 22-27.

microsponge with potential for colonic delivery

IJDDT, October-December 2014, 4(4), 58-66

Source: http://impactfactor.org/IJDDT/4/IJDDT,Vol4,Issue4,Article1.pdf

ARTICLE 48. CONTROLLED SUBSTANCES IC 35-48-1 Chapter 1. Definitions IC 35-48-1-0.1Application of certain amendments to chapter Sec. 0.1. The addition of section 9.3 of this chapter by P.L.225-2003 applies only to a controlled substance offense underIC 35-48-4 that occurs after June 30, 2003.As added by P.L.220-2011, SEC.627. Amended by P.L.63-2012,SEC.81.

© The Authors Journal compilation © 2009 Biochemical SocietyEssays Biochem. (2009) 46, 95–110; doi:10.1042/BSE0460007 Polyamine analogues targeting epigenetic gene regulation Yi Huang*, Laurence J. Marton†, Patrick M. Woster¶ and Robert A. Casero, Jr*1*The Sidney Kimmel Comprehensive Cancer Center at Johns Hopkins, The Johns Hopkins University School of Medicine, Bunting ◊ Blaustein Cancer Research Building, 1650 Orleans Street, Baltimore, MD 21231, U.S.A., †Progen Pharmaceuticals, Redwood City, CA 94065, U.S.A., and ¶Department of Pharmaceutical Sciences, Wayne State University, Detroit, MI 48202, U.S.A.