Automated dynamic fedbatch process and media optimization for high productivity cell culture process development

Automated Dynamic Fed-Batch Process andMedia Optimization for High Productivity CellCulture Process Development

Franklin Lu,1 Poh Choo Toh,2 Iain Burnett,1 Feng Li,1 Terry Hudson,1Ashraf Amanullah,1 Jincai Li11Oceanside Pharma Technical Development, Genentech, Inc., 1 Antibody Way, Oceanside,California 92056; telephone: þ(86)21-50462814; fax: þ(86)21-50461000;e-mail: [email protected] Technology Institute, Singapore 138668, Singapore

KEYWORDS: CHO cell culture; fed-batch; dynamic feeding;

ABSTRACT: Current industry practices for large-scale

capacitance; automated sampling; Nova Flex

mammalian cell cultures typically employ a standard plat-form fed-batch process with fixed volume bolus feeding.

Although widely used, these processes are unable to respondto actual nutrient consumption demands from the culture,

which can result in accumulation of by-products and deple-tion of certain nutrients. This work demonstrates the appli-

Several different modes of bioreactor operations have

cation of a fully automated cell culture control, monitoring,

traditionally been used to optimize production processes

and data processing system to achieve significant produc-

and maximize titer for monoclonal antibody production.

tivity improvement via dynamic feeding and media optimi-

Methods have varied from the simple batch and fed-batch

zation. Two distinct feeding algorithms were used todynamically alter feed rates. The first method is based

process to the more complex continuous culture or

upon on-line capacitance measurements where cultures

perfusion culture (Bibila and Robinson, 1995). Among

were fed based on growth and nutrient consumption rates

these approaches, fed-batch processes are the most widely

estimated from integrated capacitance. The second method

employed due to their ease of operation, flexibility, and

is based upon automated glucose measurements obtained

robustness. In these fed-batch processes, high monoclonal

from the Nova Bioprofile FLEX1 autosampler where cul-tures were fed to maintain a target glucose level which in

antibody yields of up to 10 g/L have been achieved through

turn maintained other nutrients based on a stoichiometric

feeding enhancement and optimization, which increase cell

ratio. All of the calculations were done automatically

productivity, maintain cell viability, and extend culture

through in-house integration with a Delta V process control

longevity (Huang et al., 2010; Yu et al., 2011). These

system. Through both media and feed strategy optimization,

strategies typically involve feeding cultures with a concen-

a titer increase from the original platform titer of 5 to 6.3 g/Lwas achieved for cell line A, and a substantial titer increase of

trated feed media either daily, continuously or at fixed

4 to over 9 g/L was achieved for cell line B with comparable

intervals with fixed feed volumes. However, this strategy

product quality. Glucose was found to be the best feed

does not take into consideration the variation in growth and

indicator, but not all cell lines benefited from dynamic

nutrient requirements that can occur in different cell lines or

feeding and optimized feed media was critical to process

even with the same cell line due to biological variability

improvement. Our work demonstrated that dynamic feed-ing has the ability to automatically adjust feed rates accord-

which in turn can lead to nutrient depletion or accumula-

ing to culture behavior, and that the advantage can be best

tion of by-products in the culture.

realized during early and rapid process development stages

Dynamic feeding on the other hand has been utilized as a

where different cell lines or large changes in culture condi-

method to adapt a process to the real time nutrient demand

tions might lead to dramatically different nutrient demands.

of cells through a variety of feeding algorithms (Wlaschin

Biotechnol. Bioeng. 2013;110: 191–205.

and Hu, 2006; Zhang et al., 2004). Early efforts in dynamic

ß 2012 Wiley Periodicals, Inc.

feeding largely focused on maintaining the cultures at a lowglucose and/or glutamine level in order to reduce by-product accumulation, in particular lactate and ammonia,

Correspondence to: J. LiReceived 5 August 2011; Revision received 22 June 2012; Accepted 26 June 2012

while also trying to balance overall nutrient demand (Gong

Accepted manuscript online 5 July 2012;

et al., 2006; Kuwae et al., 2005; Sauer et al., 2000). This was

Article first published online 1 September 2012 in Wiley Online Library

achieved by growth and nutrient consumption modeling,

coupled with more frequent manual sampling, calculation

ß 2012 Wiley Periodicals, Inc.

Biotechnology and Bioengineering, Vol. 110, No. 1, January, 2013

and manual feeding (Xie and Wang, 1994a,b). Additionally,

measurement is advantageous as an indicator for dynamic

Zhou (1994) and Zhou et al. (1995) established automated

fed-batch process due to its continuous on-line signal and

oxygen uptake rate (OUR) measurement, and used that to

does not require any multivariate chemometric analysis

estimate glucose consumption via the assumed stoichio-

(Junker and Wang, 2006; Kiviharju et al., 2008; Teixeira

metric ratio between glucose and oxygen, and then fed

et al., 2009), thus simplifying the integration into feed

accordingly to maintain a low glucose level. However,

algorithms. We also demonstrate the use of an automated

periodic manual sampling for glucose measurement was

on-line sampler to measure viable cell counts and glucose at

required to adjust the glucose to oxygen ratio as it varied

pre-determined intervals which could then in turn be used

during the course of the culture. Other efforts included

by the bioreactor control system to modulate the feed rate of

measuring and monitoring single specific nutrients, for

a complex stoichiometrically balanced feed. Previous

example, glutamine, with an automated aseptic online

methods of dynamic feeding have all required user

sampling loop, and feeding glutamine accordingly to

intervention to manually adjust feed rates making these

maintain a low level (Chee Furng Wong et al., 2005; Lee

types of experiments labor intensive to implement into

et al., 2003). More recently, dynamic feeding based on the

widespread development (Yu et al., 2011), but a fully

manual calculation of integral viable cell concentration has

automated system makes an adaptive platform feasible. We

been demonstrated to produce an optimized process

present two different models of control, a predictive method

with titers above 10 g/L (Huang et al., 2010). In all cases,

used to estimate future nutrient demand based on past

better growth and productivity were demonstrated with

consumption and growth, and a feedback mechanism used

successful control of the by-products lactate and ammonia.

to maintain the setpoint of an indicator metabolite. Both of

However, these feeding strategies are still very labor

these methods use a feed that balances key components

intensive involving frequent sampling, recalculation, and

relative to one another through an iterative analysis of

manual adjustments.

nutrient consumption. Taken together, we aim to demon-

In spite of the various successful applications, dynamic

strate a rapid, systematic method of cell culture process

feeding as a process development platform has not been

development and optimization with the capability to rapidly

explored extensively. Dynamic feeding has the benefit of

develop high titer processes.

adapting the feed strategy simultaneously with the evalua-tion of other process changes to reach an optimal process

Materials and Methods

with significantly fewer experiments. For instance, atraditional problem with the use of a predefined platform

Cell Line and Culture Conditions

during clone selection is that with a fixed feed strategy, theclone that best fits the platform will be chosen as opposed to

Two recombinant CHO cell lines, cell line A and cell line B,

the clone with the best potential. Alternatively, by allowing

expressing two distinct IgG antibodies were maintained as

the process to adapt to the growth and consumption of each

continuous seed trains in a proprietary serum-free medium

individual clone, the most efficient path to the optimal clone

under selective pressure of either methotrexate or methio-

and process can be achieved simultaneously. In addition,

nine sulfoximine. The cells were passaged every 3–4 days in

due to further developments in the technology of on-line

shake flasks at a seeding density of 0.3E6 cells/mL. These

probes, bioreactor control systems, and automated sampling

seed train cultures were kept in incubators controlled at

equipment it is of interest to evaluate such industrial

378C and 5% carbon dioxide, and were shaken at a speed of

platform processes with a completely automated dynamic

150 rpm. The inoculum for the production cultures were

fed-batch process. These advancements can supplement

cultivated in 3 L bioreactors (Applikon, Foster City, CA)

existing process measurements and adapt the cultures based

without selective pressure with a starting densities of 0.8 to

on real-time nutrient demand.

1E6 cells/mL controlled at 378C at pH 7 (Mettler Toledo,

In this work we demonstrate several distinct methods of

Bedford, MA) and 30% dissolved oxygen (DO; Broadley

on-line measurements in order to determine a dynamic feed

James, Irvine, CA) with an agitation of 275 rpm. Fed batch

rate for optimal cell culture protein productivity including

production cultures were seeded from inoculum cultures at

capacitance and online measurements of viable cell density

1.0 to 2.0E6 cells/mL in a proprietary chemically defined

and glucose. Capacitance measurement has previously been

medium without selective pressure. These cultures were

proven to be a useful tool in providing real-time biomass

controlled at the same conditions as the inoculum cultures

monitoring in fed-batch fermentations (Arnoux et al., 2005)

except for the temperature setpoint, which was shifted from

and cell culture (Opel et al., 2010). Capacitance measure-

37 to 358C on Day 2 or 3 of the production culture. For the

ments have also been successfully employed to obtain online

initial baseline studies and improved feed testing, glucose

cell concentration for feed rate calculations in the fed-batch

was supplemented separately from the rest of the feed

fermentation of Monascus sp. for yellow pigment produc-

solution as a 500 g/L solution when the glucose concentra-

tion (Krairak et al., 2000). In this work we incorporate the

tion decreased to below 3 g/L. For later glucose feedback

use of capacitance measurements as a surrogate for cell

experiments, the glucose was incorporated into the feed

growth to dynamically determine feed rate through a

solution. The culture duration for these fed-batch processes

completely automated, predictive method. Capacitance

ranged between 14 and 20 days.

Biotechnology and Bioengineering, Vol. 110, No. 1, January, 2013

Cell Culture Media

where R1 is the nutrient consumption rate defined inEquation (1), IVCþ1 is the predicted integral of viable cell

All media for the fed-batch processes were proprietary and

concentration (or surrogate such as integrated capacitance),

chemically defined. The feed medium was optimized as

from the current time to the next timepoint, V0 is the

discussed in the Results Section. Basal media was pH and

current volume of the culture, and YS is the desired

osmolality adjusted before use. Feed media was formulated

setpoint of the nutrient concentration. The final term,

without pH and osmolality adjustment.

Y0V0 � ðYSV0Þ, represents a correction factor to adjust feedvolume in the case that the predicted nutrient consumption

Fed-Batch Process

rate is inaccurate.

The standard fed-batch production process used a bolus

For glucose-based autosampler feedback, a separate

feed addition at 10% (or 5% with concentrated feed

algorithm was used in order to simplify the feed method.

medium) of culture volume, every 3 days starting on Day 3.

At each sample point, an amount of feed was added to the

Initial experiments continued the bolus feed until Day 9 but

culture to bring the glucose concentration to a target level as

later fed batch experiments with optimized feed medium

described by Equation (3)

continued the feeds every 3 days until the end of the culture.

Pumps were calibrated before each run through Delta V

(Emerson, St. Louis, MO), and the feed source was placed

on scale to monitor accuracy of additions. The dynamic

¼ target glucose ðg=LÞ � measured glucose ðg=LÞ 0 mL

glucose concentration in feed ðg=LÞ

fed batch algorithm employed in the experiments was setup through customized Delta V software. This algorithm

enabled the culture to be fed based on one of two methods, apredictive method or a feedback-based algorithm. In the

For viable cell concentration (VCC) based autosampler

predictive method, the viable cell density was monitored

feedback cases, the calculation was based on a pre-

using a BioProfile FLEX1 (Nova Biomedical, Waltham,

determined per cell consumption rate and concentration

MA) automated cell counter or using the capacitance probe.

of asparagine in the feed, as described by Equation (4).

At predetermined intervals, the current measure of the celldensity (X0), either from trypan blue counts or capacitance,and the previous measure of cell density (X

mL to add ¼ ½VCC� � V

0 � R=Freq � ½Asn�

to calculate a specific growth rate to predict the future celldensity or capacitance (Xþ1). The predicted future valuecould then be used to determine a future integrated

VCC : cell count ðcells=mLÞ

capacitance or integrated viable cell count. A nutrient

V0 : culture volume ðmLÞ

consumption rate (R

R : asparagine consumption rateðmmol asn=cell dayÞ

1) could then be calculated using

the current nutrient concentration (Y

Freq : sampling frequency ð1=dayÞ

0), previous nutrient

concentration (Y�

Asn : asparagine feed concentrationðmmol asn=mLÞ

1), previous feed volume ( F�1), feed

concentration (Yc), current tank volume (V0), and previoustank volume (V�1) to determine the total amount of feed percell per unit time required as shown by Equation (1)

In Process and Offline Measurements

Nutrient consumption rate

Online capacitance (Fogale Biotech, Cambridge, MA)readings were taken continuously during the runs of the

¼ previous � current þ fed ¼ Y�1V�1 � Y0V0 þ F�1YC

predictive model to facilitate the feeding algorithm. The

capacitance reading was taken directly from the probe

measurement with parameters set as described in Opel et al.

Alternatively, nutrient consumption rates from previous

(2010) and every 4 h these readings were used as described in

experiments could be used as estimates. Once the nutrient

the fed-batch process above. The offline VCC, viability,

consumption rate was determined, the final feed rate could

pH, ammonia, osmolality, pCO2, pO2, Caþþ, Kþ, Naþ,

be calculated by Equation (2):

glutamine, glutamate, glucose and lactate were all moni-tored using a BioProfile FLEX1 (Nova Biomedical).

Autosamplers were setup and cleaned as described in

Feed volume ¼ predicted consumption ðmmolÞ

concentration in feed ðmmol=mLÞ where

Derfus et al. (2009). Amino acid analysis and vitamin

predicted consumption ¼ consumption rate

analyses (by high performance liquid chromatography,HPLC), as well as trace element analysis (by inductively

� predicted IVC � ðcurrent nutrient concentration

coupled plasma mass spectrometry, ICP-MS) were also

� desired nutrient concentrationÞ

performed after each experiment. Titer was measured

¼ ðR1IVCþ1Þ � ðY0V0 � ðYSV0ÞÞ

through HPLC with Protein A columns.

Lu et al.: Automated Dynamic Fed-Batch Process and Media Optimization

Biotechnology and Bioengineering

Antibody Product Quality Analysis

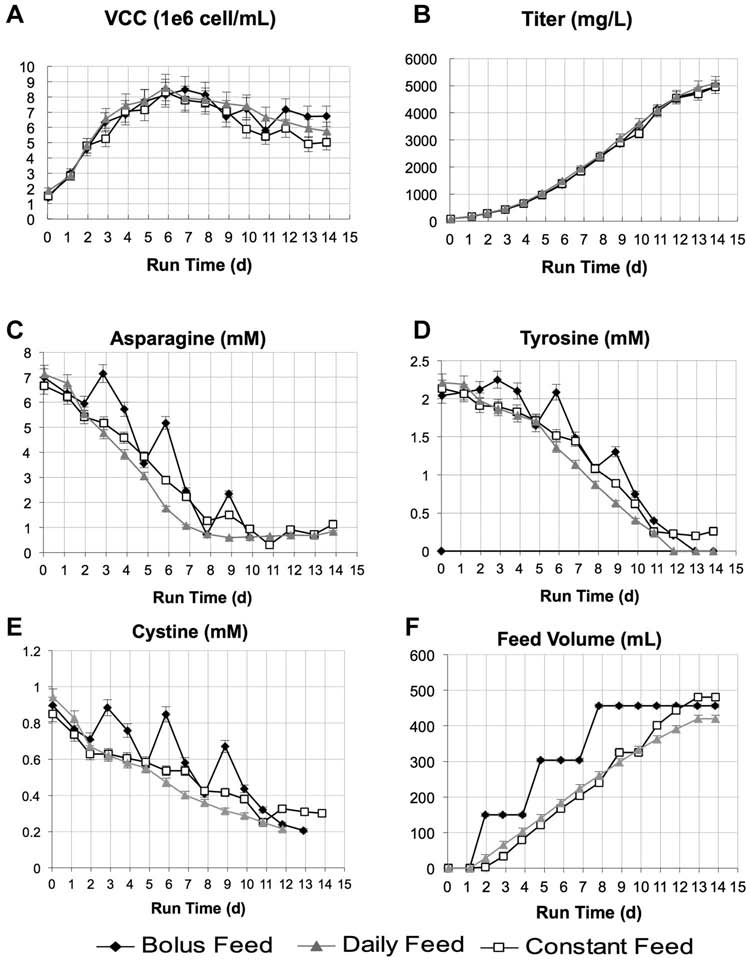

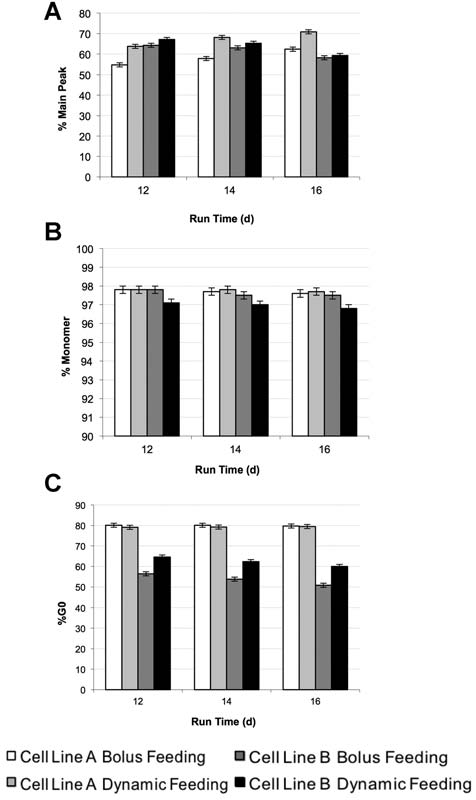

defined feed media and to evaluate the impact of feedtiming. The cultures were fed with the same feed medium,

The product quality attributes of antibodies, including level

either by bolus feeding (10% of working volume on Day 2, 5,

of aggregation, acidic and basic variants, and various

and 8), daily feeding (adjusted daily based on VCC), or

glycoforms were measured and compared. The various

continuous feeding (1.8 mL/L/h starting at Day 2). All cases

product quality analysis methods were previously described

were designed to deliver similar total feed volumes (Fig. 1F)

(Li et al., 2012).

and resulted in similar growth and titer profiles (Fig. 1A andB). This initial data suggested that when the total amount ofnutrients is controlled, a variety of feed timings and volumescould still be used to produce comparable results. While

Errors, Uncertainties, and Reproducibility of Results

growth and titer were not impacted by feed timing, amino

Most data presented here are from representative singlet

acid time course profiles revealed that all three cultures were

conditions as the overall effort was an iterative process so

exhausted or limited in several key nutrients including

each experiment varied slightly. Error bars presented are

cysteine, asparagine, and tyrosine during the late stage of the

based on error of analytical measurements only and are

run (Fig. 1C–E) which may have led to slowed product

described in each corresponding figure. We feel confident in

accumulation during the late stage of the culture.

the results and general applicability of the method, as severalsets of iterative conditions were studied. We saw similarimprovements in two cell lines (Fig. 9) with three different

Feed Media Design and Optimization

on-line inputs (capacitance, glucose, and OUR) and theperformance trend was consistent throughout the optimi-

The platform feed medium was redesigned and refined after

zation process (Table I).

several experiments according to the flow chart shown inFigure 2 to obtain a stoichiometrically balanced feedmedium. For this iterative method, several experiments

were required in order to assess the effectiveness of thefeeding method for maintaining consistent nutrientconsumption rates since adjustment of the feed could

Baseline Data (Platform Feed Formulation,

potentially change the relative consumption rates. Daily

amino acid concentrations were used to calculate daily

In order to provide baseline data, cell lines A and B were

consumption rates that were then averaged to determine

evaluated in a standard fed-batch process as described in the

an overall consumption rate. The relative ratios for all

Materials and Methods Section. These cell lines were chosen

components of the feed medium were then normalized to an

due to their high titer and high nutrient consumption rates

indicator metabolite. When cultures were fed based on the

in order to maximize the potential improvements of

indicator metabolite, other components were supplemented

dynamic feeding. The results of cell line A are shown in

in stoichiometric amounts to avoid exhaustion or over

Figure 1. Nutrient data was also collected in the initial

accumulation. In these studies, asparagine was selected

baseline experiments in order to redesign the chemically

as one benchmark metabolite because of its role as one

Evolution of feed media.

Feed concentration of

unlisted metabolites

Zinc sulfate (mg/L)

Ferric citrate (mg/L)

Other amino acids

1.4� leucine, lysine, serine

Glycine, threonine, valine,

(others unchanged)

isoleucine, leucine, serine 1.8–2.5�

of CDF1 (others 1.5� of CDF1)

Osmolality (mOsm/kg)

Titer (cell line B)a

4.1 � 0.2 (3 feeds to Day 9)

6.0 � 0.3 (3 feeds to Day 9)

7.0 � 0.4 (5 feeds to Day 14)

8.6 � 0.4; 9.1 � 0.5

aTiter ranges (�t) are based on analytical error.

Biotechnology and Bioengineering, Vol. 110, No. 1, January, 2013

Figure 1. Three cultures of cell line A, designed to receive about the same volume of a chemically defined feed formulation (CDF1) were evaluated with either bolus feeding(10% WV on Day 2, 5, 8), daily feeding (adjusted daily based on VCC), or continuous feeding (1.8 mL/L/h starting at Day 2). A: VCC; (B) titer profiles of baseline fed-batch runs weresimilar independent of feeding method; (C) asparagine; (D) tyrosine; (E) cystine amino acid profiles indicating nutrient limitation in later part of culture; and (F) total feed volumeprofile. Error bars are based on analytical accuracy of measurements: VCC � 5%, titer � 5%, amino acids � 5%, and feed volume (by weight) � 5 g.

of the key energy sources in the tricarboxylic acid (TCA)

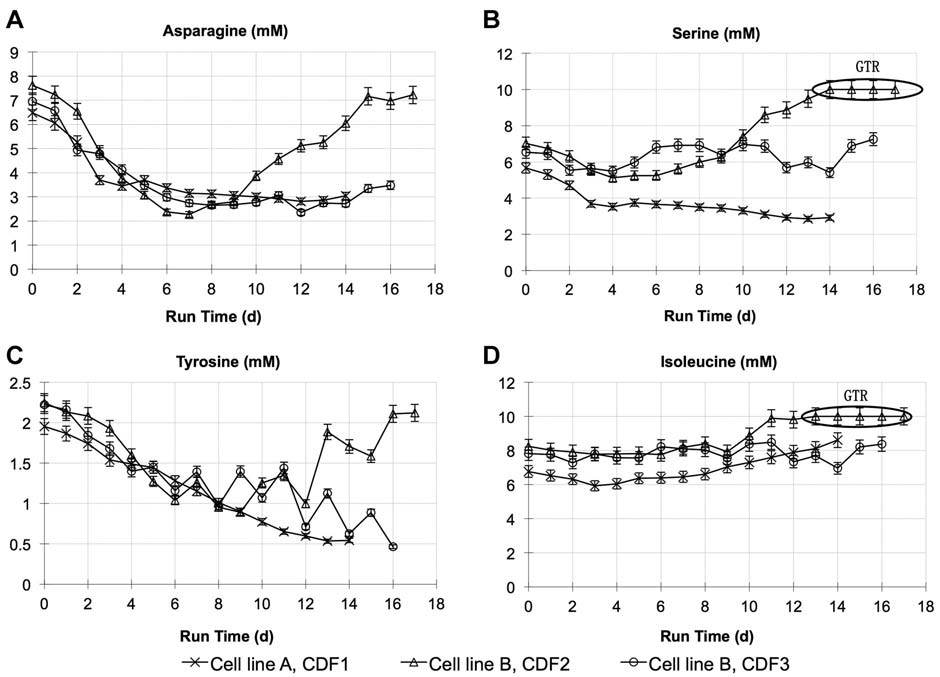

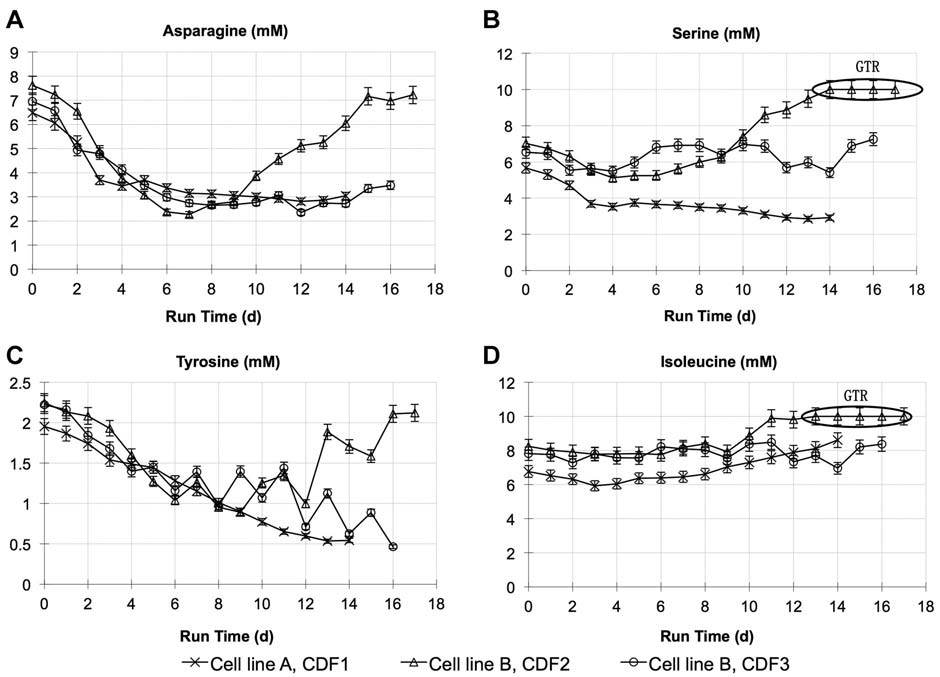

The evolution of the feed media is described in Table I. As

cycle and its relatively consistent consumption rate

shown in Figure 1, cultures with the initial platform feed

throughout our baseline study cultures. In addition,

showed depletion of several amino acids. Therefore, the

asparagine is regarded as a key amino acid for product

original platform feed was adjusted with higher levels of

synthesis, as depletion of asparagine had been shown to

asparagine, tyrosine, leucine, lysine, and serine to create

lead to decreases in cell specific productivity (unpublished

chemically defined feed #1 (CDF1). In addition, zinc and

observations). Other metabolites such as glucose were

iron levels were also increased in CDF1. With CDF1, the

also used as an indicator due to its key role as a primary

culture was able to maintain appropriate levels of most of

energy source.

the amino acids, for example, asparagine, tyrosine, serine,

Lu et al.: Automated Dynamic Fed-Batch Process and Media Optimization

Biotechnology and Bioengineering

and isoleucine. However, the total feed volume increasedabout 40% compared to the control culture (data notshown), resulting in significant dilution and thus limitingincrease of volumetric productivity. The majority of the feedcomponents were then concentrated by 2� in order tominimize dilution effects, and relative ratios were furtheradjusted (chemically defined feed #2, CDF2). CDF2 wastested for cell line B with asparagine as indicator metabolite,and average asparagine consumption rate from platformbolus feed culture was used as pre-determined nutrientconsumption rate. However, significant accumulation ofasparagine as well as serine and isoleucine was observed, asactual asparagine consumption rate on cell line B culturewas lower than predicted. The overall concentration of thefeed medium was then lowered slightly to 1.5� of CDF1 andratios of several components were further refined forthe final version, chemical defined feed #3 (CDF3), toaccommodate the changes in consumption rates. This

Figure 2. Iterative method of a complex stoichiometrically balanced feed.

resulted in balanced nutrient profiles, as shown in Figure 3of asparagine, tyrosine, serine, and isoleucine profiles.

In addition, vitamin and trace metals profiles were alsomonitored and adjustments were made throughout the feedmedium optimization (data not shown). The titer results in

Figure 3. Amino acid profiles of (A) asparagine, (B) serine, (C) tyrosine, and (D) isoleucine during dynamic feeding with evolved feed medias CDF1, CDF2, and CDF3 with bothcell line A and B. Error bars are based on analytical accuracy of measurements: amino acids � 5%. GTR (greater than measurement range of 10 mM).

Biotechnology and Bioengineering, Vol. 110, No. 1, January, 2013

Table I showed the performance improvement trends for cell

that of the typical PID control. Two primary advancements

line B throughout the optimization process.

were key to these developments: the integration of on-lineprocess monitoring which was able to provide realtime analysis of key variables (i.e., capacitance) and theautomation of at-line sampling that is typically done by

Design of Dynamic Feeding algorithm

hand by researchers using Nova Bioprofile Automated

Two different types of dynamic feeding algorithms were

Sampler system. In collaboration with Nova Biomedical, we

employed in this work. The predictive method utilized an

were able to build a custom OPC module to read additional

online indicator of cell growth and calculated the expected

parameters that could be measured on an adaptable

growth rate and cell density in order to estimate future

nutrient demand. The alternative approach was a feedback-

Figure 4 depicts the set up of the automated fed-batch

based approach in which the historical nutrient consump-

process. Initially, a signal (capacitance, OD, OUR, cell

tion is used to determine amount of feed to maintain an

count, or glucose) was collected in order to assess the

indicator metabolite at a target. With the automated

current state of the bioreactor. Once the current state of the

sampling method, the sampling interval is set frequent

bioreactor had been assessed, previous data could also be

enough (�6 h) to avoid dramatic changes in cell mass and

used to predict future nutrient demand. In the case of

the target concentration is set high enough to avoid

capacitance, the specific growth rate was coupled with a

exhaustion between feeding intervals. In either method,

predetermined nutrient consumption rate to account for

dynamic feeding is not being used in a nutrient limited

changes in cell mass before the next feed point. Finally, after

mode to alter metabolism, but solely as a means to

each pre-determined interval, the feed pump was activated

determine how much and how often to feed, which may

to supply the required volume of feed.

avoid potential changes in product quality due to altered

In order to account for noise and aberrant readings,

metabolism (Chee Furng Wong et al., 2005). In addition,

correction factors were incorporated into both algorithms.

the dynamic feed was restricted to small bolus feeds that

For the predictive methods an additional term were built in

occurred several times a day. Consequently, nutrient

to the algorithms to handle over or underfeeding (the

composition was never fully static, but was controlled

second term of Equation 2).For the feedback method, the

within desired ranges to optimize productivity.

response to fluctuation is built into the feedback control so

One of the key advancements of this work was integration

that if at any one data point, an excess of feed is added, the

of our feeding algorithms into our control system. Delta V is

feed volume added will be reduced or eliminated upon

a process control platform that can be easily scaled for large

the next measurement. Neither of these algorithms are able

bioreactor networks. In this work, we were able to build

to immediately discard an errant data point, which is a

custom modules within the control system that linked to

weakness of the system, as an incorrect measurement could

novel inputs to build an additional layer of control beyond

lead to a large spike of unneeded feed. While not

Figure 4. Design of automated dynamic feeding system.

Lu et al.: Automated Dynamic Fed-Batch Process and Media Optimization

Biotechnology and Bioengineering

implemented for these experiments, a criteria could be

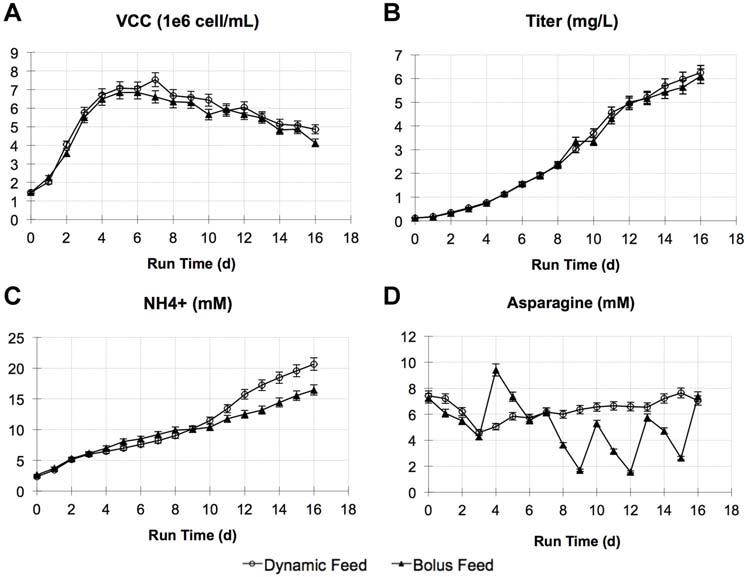

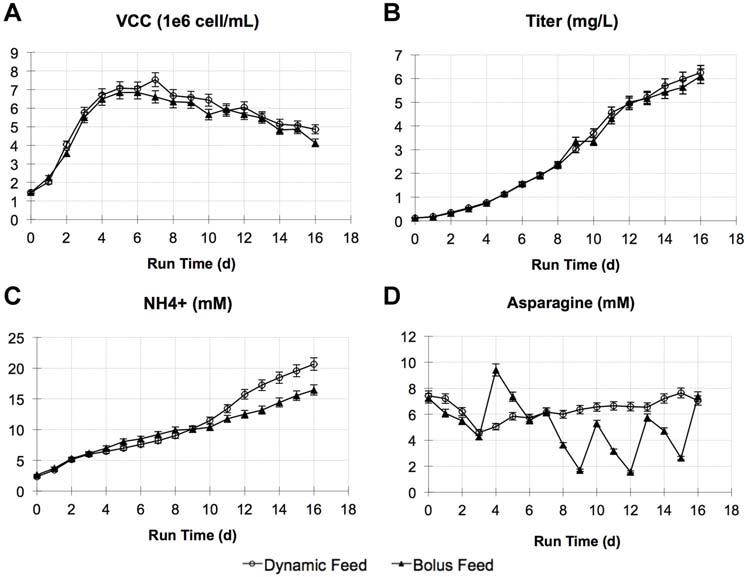

productivity profiles (Fig. 5A and B). Ammonium increased

implemented that would trigger a re-calibration and

more rapidly in late phase of the dynamic feeding culture

recalculation of feed addition if, for instance, the calculated

(Fig. 5C), potentially due to higher levels of asparagine

consumption rate changed more drastically than expected.

available, which may have resulted in higher rate of

These sort of error checks would be simple for an automated

deamidation to aspartatic acid. Asparagine concentration

method to incorporate once bi-directional communication

was well maintained throughout the cultures, although there

with analytical instruments is enabled. Currently, this is

were more day-to-day changes for the bolus feeding case

possible with the Nova Flex and was in development at the

compared to the dynamic feeding case (Fig. 5D). Other

time of this work.

nutrient and metabolism profiles were also similar betweenthe two cultures (data not shown). Titer reached 6.1 and6.3 g/L for the bolus and dynamic feeding cases, respectively,

Capacitance Based Predictive Method Using Optimized

which represents about 25% increase when compared to the

Feed Medium: Cell Line A

platform bolus feeding cultures shown in Figure 1. Theimprovement in titer appeared to be primarily due to

The automated system described above was first attempted

optimization of feed formulation and cell line A was not

using the predictive model with online capacitance

sensitive to the feeding frequency using the optimized feed

measurement. In addition, the feed medium formulation

was optimized from the original platform feed medium afterseveral iterative experiments. Figure 5 shows the resultsusing the optimized feed medium CDF3 for cell line A. The

Capacitance Based Predictive Method Using Optimized

dynamic feed was based on capacitance measurement and

Feed Medium: Cell Line B

was added every 4 h. A bolus feed culture was also performedfor comparison, where a feed volume of 5% initial culture

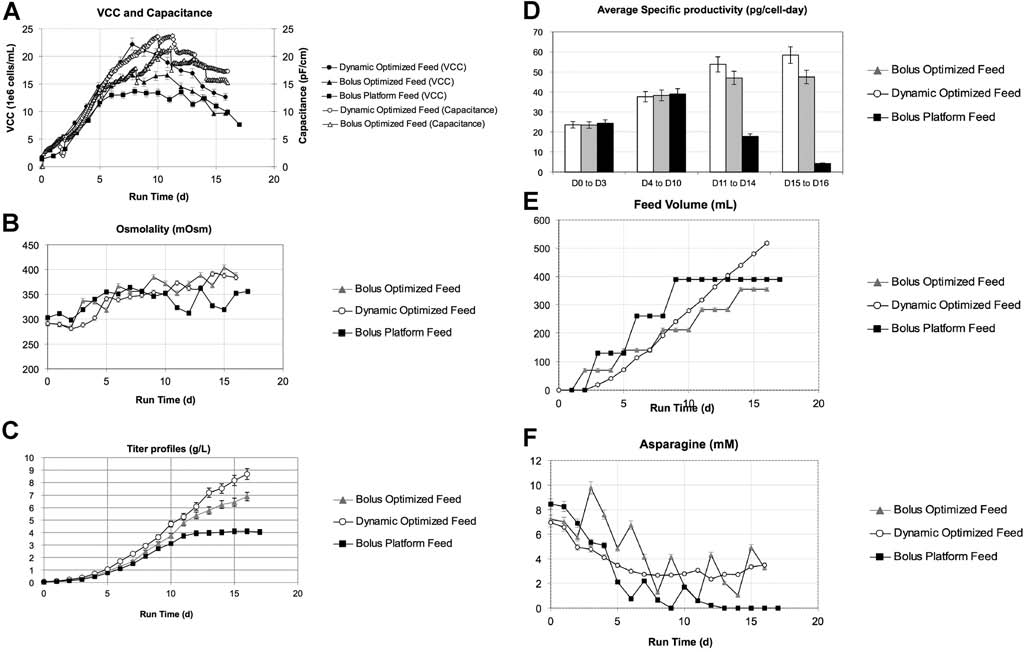

The capacitance-based dynamic feeding method was also

volume was delivered every 3 days until Day 15. Overall, the

applied to cell line B with the same optimized feed medium

dynamic feeding case and the manual bolus feeding case had

CDF3. Cell line B had marked difference on growth and

very similar performance, as shown by the growth and

nutrient consumption rates compared to cell line A (data

Figure 5. Two cultures of cell line A were tested with optimized feed medium (CDF3) using either the standard bolus feeding method (5% every 72 h) or using the dynamicfeeding method with capacitance as on-line feedback signal (fed every 4 h). Comparison of (A) VCC, (B) titer, (C) ammonium, and (D) asparagine profiles. Error bars are based onanalytical accuracy of measurements: VCC � 5%, titer � 5%, ammonium � 5%, and amino acids � 5%.

Biotechnology and Bioengineering, Vol. 110, No. 1, January, 2013

not shown), and thus the pre-determined feeding rate had to

and physiological state in addition to biomass (Opel et al.,

be adjusted for each cell line. Specifically, the asparagine feed

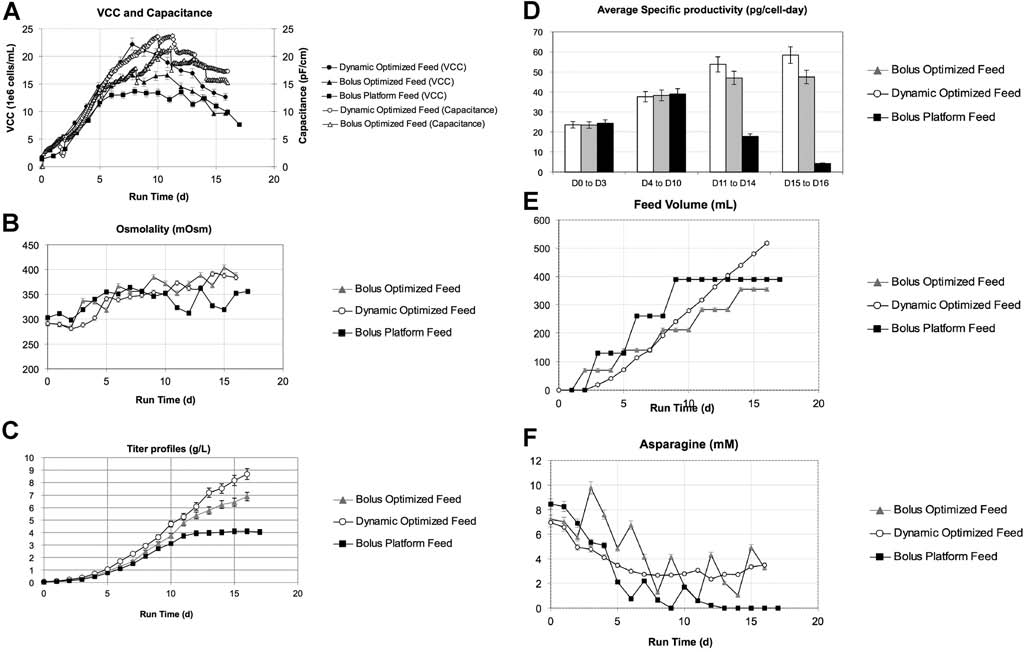

2010). Titer was also dramatically improved with the

rate was reduced by about 30% to account for lower specific

optimized feed formulation. Combined with dynamic

asparagine consumption rate. For the control case, manual

feeding, cultures were able to reach titers up to 8.6 g/L, a

bolus feeding was done every 3 days at 5% initial culture

two-fold improvement over the baseline process (Fig. 6C).

volume using the same CDF3 feed medium. The results are

Cell specific productivity was similar during the early stage

shown in Figure 6. In addition, results from the original

of culture, and the capacitance based predictive method

platform bolus feed culture are also depicted in Figure 6 for

maintained productivity at higher levels and for a longer

period than bolus feeds (Fig. 6D). The bolus feed case with

Cell growth was significantly higher in the dynamic

the same optimized feed was also improved from the

feeding case than both the improved bolus feed case and the

baseline, reaching 7 g/L titer, indicating that the rebalancing

initial platform bolus feed case (Fig. 6A). Peak density was

of the feed as well as higher inoculation density were also

reached around Day 8 in both improved bolus feed and

significant contributions to the increase in titer. However,

dynamic feeding cases. Osmolality was maintained below

even in the optimized bolus feed case shown here, rapid

400 mOsm/kg at the end of the culture, indicating absence of

changes of over 50 mOsm/kg still occurred after each

significant metabolite accumulation (Fig. 6B). Capacitance

bolus feed, potentially negatively impacting growth and

profiles tracked closely with offline VCC values until peak

productivity relative to the dynamic feeding case. In

VCC was reached. Capacitance then continued to increase

addition, the total feed volume was not controlled as in

for several days before beginning to decrease around Day 11.

the baseline studies. The dynamic feed culture actually used

The divergence between capacitance and VCC profiles had

approximately 50% more total feed volume (Fig. 6E) over

been reported previously, as capacitance depends on cell size

the entire culture duration compared to the bolus feed

Figure 6. Two cultures of cell line B were tested with CDF3 using either the standard bolus feeding method (5% every 72 h) or using the dynamic feeding method withcapacitance as on-line feedback signal (fed every 4 h). Both cultures also incorporated a higher inoculation density of 2e�6 cells/mL to increase build up of cell mass. The platformbolus feed process (with initial platform feed medium and lower inoculation density) is shown for reference: (A) VCC (solid symbols) and capacitance (open symbols) profiles, steepdrops in capacitance profile in the optimized bolus case were due to volume changes due to feeds; (B) osmolality profiles, (C) titer, (D) average specific productivity, (E) total feedvolumes, and (F) asparagine concentration profiles. Error bars are based on analytical accuracy of measurements: VCC � 5%, osmolality � 5 mOsm, titer � 5%, specificproductivity � 7% (based on propagation of error), feed volume (by weight) � 5 g, and amino acids � 5%.

Lu et al.: Automated Dynamic Fed-Batch Process and Media Optimization

Biotechnology and Bioengineering

culture, although no amino acids dropped below detectablelevels (0.2 mM) in either case. While the lack of nutrientexhaustion demonstrated the successful redesign of the feedformulation using the iterative method (Fig. 6F), it alsoindicated that feeding the additional volume in the dynamicfeeding case led to greater nutrient consumption andincreased antibody production. These differences under-score the possibilities that different feed algorithms canresult in alternative feed volumes that could result in evenhigher titers. Consequently, simply searching for nutrientexhaustion might not be sufficient to determine when aprocess has reached an optimal feed regime.

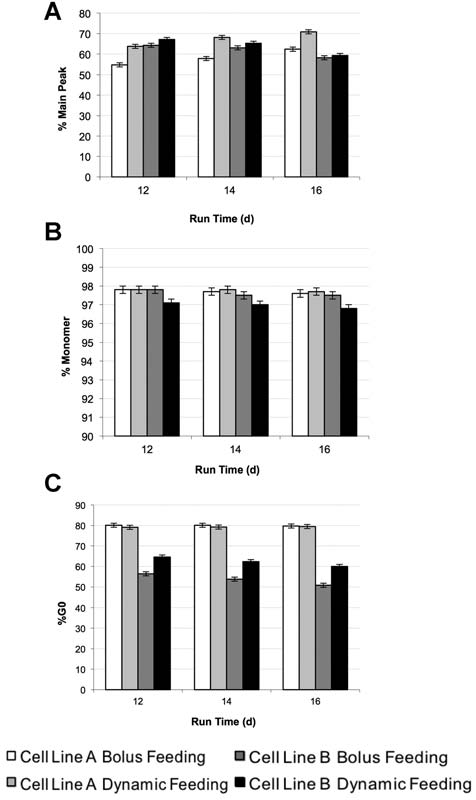

A key aspect of process improvement is product quality.

Differences in product quality have been observed inprevious applications of dynamic feeding that was focusedon altering cellular metabolism to improve processproductivity (Chee Furng Wong et al., 2005). However,in our case our feeding algorithms are not designed tooperate in nutrient limited mode, but to more efficientlypredict the demand of the culture and adjust feed accordingto shifts in cell density and cell physiology. Consequently, inour cases only minor differences in key product qualityattributes were observed that were all within acceptableranges for typical molecules (Fig. 7).

Autosampler Based Feedback Control Method UsingOptimized Feed Medium: Cell Line B

As an alternative to a predictive model of nutrient demandused in previous studies, we explored a direct feedbackmechanism where feed rates were altered dynamically tomaintain a preset target of an indicator metabolite. From thelimited number of metabolites directly measured by theBioProfile FLEX instrument, glucose was chosen as a keyindicator of metabolism. Glucose has the advantage of beinga direct indicator of nutrient consumption that inherently

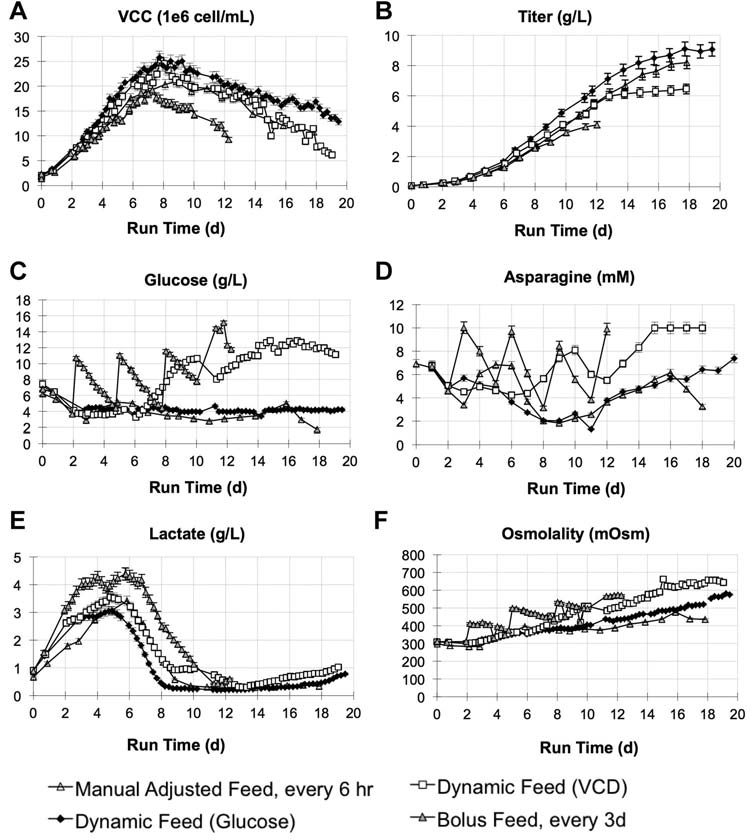

Figure 7. Product quality comparison between dynamic feeding and bolus

incorporates changes in cell growth and volumetric

feeding cases. A: %Main peak of charged variants as measured by iCIEF at Day12, 14, and 16 using the capacitance based predictive method for the two test cell lines.

consumption rate. From the capacitance based predictive

B: %Monomer analysis of product by size exclusion chromatography, (C) %GO glycan

dynamic feeding study, it was observed that there was a

analysis by capillary electrophoresis. Error bars are based on analytical accuracy of

relatively constant ratio between glucose consumption rate

measurements: monomer � 0.2%, charge variants � 1%, and glycoforms � 1%.

and the asparagine consumption rate throughout theculture. This suggested that glucose could be a surrogateindicator for the previously asparagine balanced feed

this method, additional components could be modified or

formulation (CDF3) to dynamically feed the cultures.

added easily to a chemically defined feed as long as they are

Feed rate in glucose feedback control is determined by

balanced relative to other nutrients based on their

Equation (3) described in the Materials and Methods and by

consumption rates.

in-process glucose measurements. The glucose feedback

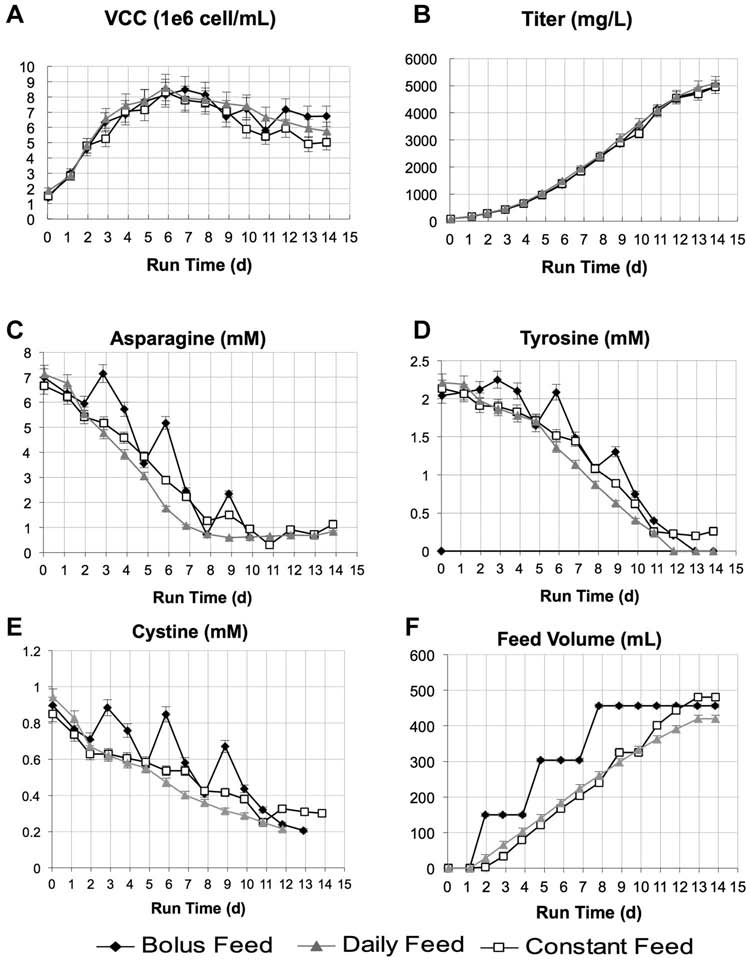

Figure 8 shows the results of the autosampler based

method benefits from incorporating multiple sources of

dynamic feed back control study. In addition to feeding

variability such as changes in cell mass and metabolism into

based on the measured glucose concentration, VCC was also

a single direct input that could be used to determine the feed

used as a feeding indicator in this same study. For the

glucose-based feeding, the target glucose level was set at 5 g/L,

The feed medium used in this study had one change from

which was chosen based on previous capacitance based

CDF3, which was used in the experiment described in

feeding study. For the VCC-based feeding, feed rate was

Figure 6. Glucose, which had previously been added

calculated automatically according to Equation (4) in the

separately as a second feed, was added to the feed medium

Materials and Methods Section. In addition, a fourth case

and balanced stoichiometrically with other metabolites. The

from a separate experiment, labeled as ‘‘Manual adjusted

rest of the CDF3 composition remained unchanged. With

feed, every 6 h'' was also included for comparison, where the

Biotechnology and Bioengineering, Vol. 110, No. 1, January, 2013

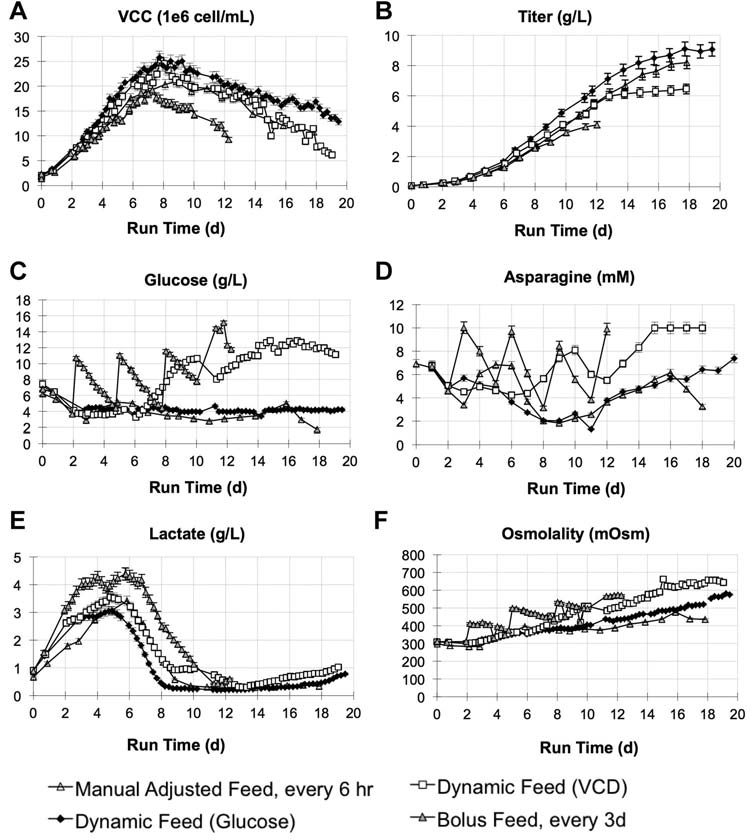

Figure 8. Auto sampler based dynamic feeding results of cell line B. Cultures were inoculated at initial VCC of 2.0e�6/mL and feeding with CDF3 was initiated on Day 2. For theglucose and VCC-based feeding, cultures were sampled every 6 h via the autosampler, and fed automatically based on Equations (3) and (4) after each sampling. A fourth case froma separate experiment, labeled as ‘‘manual adjusted feed, every 6 h'' was also included for comparison, where the feed medium was also delivered every 6 h, but no auto samplerwas used and feed volume was preset once a day based on off-line glucose measurement. The daily adjustment on feed volume was done to target culture glucose level of between4 and 6 g/L. The bolus feed case was fed every 3 days at 6.7% initial culture volume. A: VCC and (B) titer profiles indicating cell mass and productivity improved with glucosefeedback. C: Glucose and (D) asparagine profiles illustrating direct and indirect metabolite control through dynamic feeding. E: lactate and (F) osmolality profiles. Error bars arebased on analytical accuracy of measurements: VCC � 5%, titer � 5%, glucose � 0.2 g/L, asparagine � 5%, lactate � 5%, and osmolality � 5 mOsm.

feed medium was delivered in the same frequency as with the

nutrient accumulation (Fig. 8C, D, and F). This may be due

glucose based feeding, that is, every 6 h. But no auto sampler

to the fact that VCC is an indirect indicator of nutrient

was used and feed volume was adjusted only once a day

consumption and the total cell mass may not be an accurate

based on off-line glucose measurement so that the same

indicator of changing metabolic activity. As a result, the

feed volume would be used four times before the next

continual overfeeding and resulting osmolality increases

adjustment. The daily adjustment on feed volume was done

may have led to more rapid reduction in VCC (Fig. 8A) and

to target culture glucose level of between 4 and 6 g/L. The

reduced productivity. The bolus feeding case (fed every

design can be interpreted as manual dynamic feeding.

3 days at 6.7% initial culture volume) did not perform as

The highest titer of 9.1 g/L was achieved using the glucose

well in this study, with culture viability dropping to <60%

feedback method (Fig. 8B). In the auto sampler based VCC

by Day 12 and titer reaching 4.1 g/L. Compared to the bolus

feedback case, glucose, osmolality, and asparagine levels

feeding case in Figure 5 where titer reached 7 g/L, a key

were increasing late in the culture, indicating potential

difference between the two cultures was the increased feed

Lu et al.: Automated Dynamic Fed-Batch Process and Media Optimization

Biotechnology and Bioengineering

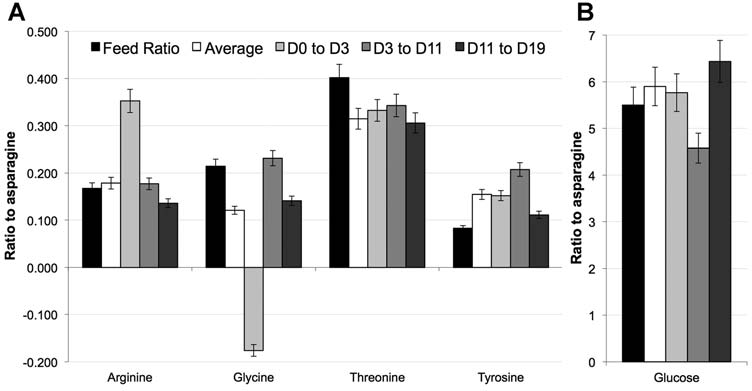

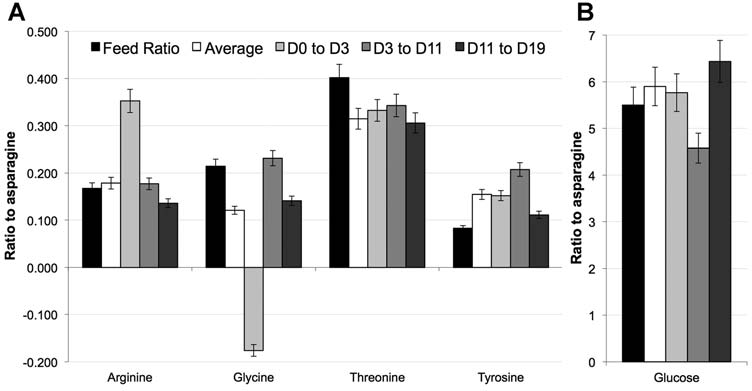

Figure 9. A: Ratio of feed concentrations and consumption rates of arginine, glycine, threonine, and tyrosine relative to feed concentration and consumption rates ofasparagine in feed versus consumption rates in various stages of culture for auto sampler based glucose feedback culture: (black) indicates ratio in feed medium, (white) indicatesconsumption rate across entire run, (light gray) consumption rate from Day 0 to Day 3, (gray) consumption rate from Day 3 to Day 11 and (dark gray) consumption rates from Day 12to Day 19 based on amino acid analysis of cell culture supernatants by HPLC. B: Ratio of glucose feed concentrations and consumption rates to asparagine feed concentrations andconsumption rates for auto sampler based glucose feedback case. Error bars are based on analytical accuracy of measurements and propogation of error: amino acids ratio � 7%,glucose ratio � 6.7% (based on glucose error of 0.2 g/L and average glucose measurement of 4.5 g/L).

volume from 5% to 6.7% initial culture volume per feed,

with the objective of increasing total feed volume to matchthe dynamic feeding case. However, the bolus feed case

Most industrial mammalian cell culture processes still use

might have suffered from apparent high osmolality and high

manual bolus feeding methods for nutrient feeding (Kelley,

nutrient concentration shock accompanied by each feed, as

2009). This is in contrast to an industrial microbial

each bolus feed added about 100 mOsmo to the culture

fermentation process where automatic, dynamic feeding

(Fig. 8F). The fourth case with the daily manual adjusted

often is necessary to avoid nutrient over-accumulation and

feed rate performed quite well, reaching titer of 8.2 g/L,

waste product formation. Examples include widely used

which was only slightly lower than the 9.1 g/L reached by the

dissolved oxygen (DO-stat) or pH (pH-stat) based feeding

glucose-based dynamic feeding case and comparable with

strategies for E. coli fermentation (Chen et al., 1997; Kim

the 8.6 g/L reached by the capacitance-based dynamic

et al., 2004). The difference in practice is largely due to the

feeding case in Figure 6.

fast metabolism of microbial cells in comparison to

When looking at the metabolite and nutrient profiles, the

mammalian cells and hence the perception that mammalian

glucose feedback case and the daily manual adjusted case

cultures do not need to be fed so frequently. In this work,

tracked very closely in glucose, lactate, asparagine, and

part of our objective was to understand whether given the

osmolality (Fig. 8C–F). In contrast, the VCC-based dynamic

same feed medium, the feeding strategy and frequency

feeding case and the bolus feed case both had higher glucose,

difference would lead to different culture performance.

asparagine, and osmolality levels.

Little has been reported on such comparison studies. In their

Even with glucose as a direct indicator of metabolism, the

work, Po¨rtner et al. (2004) did compare the various control

relative consumption rates of other components varied

and feed strategies for a hybridoma cell line expressing a

during the culture, and in some cases the overall

Mab. However, the studies with the various feed strategies

consumption rates also differed slightly than predicted

were not conducted in parallel; rather they were done over

from previous studies (Fig. 9A and B). For instance, the

several years, when specific Mab productivity varied

average consumptions rate (white bar) of arginine and

significantly. The feed medium used for the studies also

glucose matched well with the ratios predicted in feed

varied slightly. Thus strict comparison on productivity

formulation (black bars), but other components such as

across the different methods was not possible. Many other

tyrosine and glycine showed slight differences from expected

reports compared performance between batch culture and

relative consumption. In addition, as expected, the relative

optimized fed-batch culture, but again not among fed-batch

consumption rates also varied throughout the length of the

culture modes with the same feed medium (Xie and Wang,

culture from relatively minor changes of glucose to more

1994a,b, 1996; Xie et al., 1997; Yu et al., 2011; Zhou et al.,

dramatic shifts of components such as glycine.

1995, 1997). To our knowledge, our work is the first that

Biotechnology and Bioengineering, Vol. 110, No. 1, January, 2013

Summary of comparisons between preset bolus feed and automatic dynamic feed cultures.

Bolus (daily adjusted)

1.91 (1.18 on Day 12)

6.5 (5.4 on Day 12)

640 (395 on Day 12)

1.64 (1.01 on Day 12)

9.1 �0.5 (6.3 � 0.3 Day 12)

Bolus (daily adjusted)

530 (335 on Day 12)

1.36 (0.86 on Day 12)

8.2 � 0.4 (5.4 � 0.3 Day 12)

aAdjusted based on 1.45 L initial culture volume, �5 g.

bTiter ranges (�5%) are based on analytical error.

cNutrient depletion seen on all three cultures.

dBolus feed rate changed from 5% to 6.7%. High nutrient accumulation, high osmolality seen on the culture with bolus, every 3-day feeding, which resulted

in early termination of bolus culture.

eThe glucose concentration was adjusted to 133 g/L (739 mM) in CDF3 for this experiment to combine a previously separate glucose and nutrient feed into

one solution.

offers direct comparison between manual bolus feeding and

noted, however, that for manual bolus feeding to work

automatic dynamic feeding with industrially relevant and

optimally, appropriate feed dose, and feeding frequency still

high producing cell lines. We offered four sets of data

need to be established for different cell lines and processes.

(Figs. 1, 5, 6, and 8) across two cell lines for the direct

This is especially true for highly concentrated feed medium,

comparison. Table II summarized the studies by highlight-

for example, CDF3, where feeding in every 3 days at 5%

ing the feeding strategy, frequency and total feed volume.

initial volume seemed not enough for cell line B, and feeding

Each set of the studies used exactly the same feed medium,

in every 3 days at 6.7% initial volume resulted in large

with the only difference being feeding strategy and

osmolality and nutrient shock.

frequency. The studies shown in Figures 1 and 5 show

In essence, the key advantage of dynamic feeding, when

basically identical performance between manual bolus

coupled with feedback control, is the ability to automatically

feeding and dynamic feeding for cell line A, whereas studies

adjust feed rates according to culture behavior, aka, feed by

on Figures 6 and 8 show higher titer with the dynamic

demand, thus avoiding either under-feeding or over-feeding

feeding case than the bolus feeding case for cell line B.

of the cultures. The advantage can be best realized during

Consequently, improvements from dynamic feeding will

early and rapid process development stages where different

vary based on relative sensitivity of cell line, which may be a

cell lines or large changes in culture conditions might lead to

combination of sensitivity to large shifts in osmolality from

dramatically different nutrient demands, making it impos-

bolus feeds and sensitivity to variations in metabolites that

sible to determine feed rates beforehand. Conversely, once a

may alter nutrient uptake and metabolism. For some cell

process is well established, a fixed rate, predefined bolus

lines, such as cell line A, this difference may be negligible.

feeding method could very well deliver similar performance.

An interesting observation from this work was that the

The actual dynamic feed profiles (Figs. 1F and 6E) of this

relative performance among the cases appear to be

work appear to be relatively constant, where a continuous

correlated with total feed volume, with the total feed

feed could also potentially replicate results while simplifying

volume approximately the same between the feeding

implementation. However, these simplifications require first

methods for Figure 1 studies and Figure 5 studies,

performing dynamic feeding experiment to determine the

respectively, whereas for Figure 6 studies, feed volume

appropriate feed rate. In addition, even in well established

was about 1.5� higher with the dynamic feeding case. This

manufacturing processes, the bolus strategy does not take

suggests that it is possible to achieve similar culture

into consideration the variation in growth and nutrient

performance when similar volumes of feed are delivered via

requirements that can occur due to variations in parameters

different feeding methods. Consequently, with further

like inoculation density, raw materials or cell age, which in

adjustments a manual bolus feed could potentially achieve

turn can lead to nutrient depletion, or accumulation of by-

the same titer as a dynamic feed with cell line B. However,

products in the culture.

two key points need to be considered a priori. The total

In our efforts, we evaluated both the capacitance-based

bolus feed volume would need to be predetermined, and the

predictive method and the auto sampler-based feedback

frequency of bolus feeding needs to be optimized for

control method. Similar performance was achieved between

different feed medium and different processes. It should be

the two methods. The predictive method requires accurate

Lu et al.: Automated Dynamic Fed-Batch Process and Media Optimization

Biotechnology and Bioengineering

modeling of culture growth rates or nutrient consumption

The authors are grateful for the valuable contributions and technical

rates (Dowd et al., 2001a,b; Kurokawa et al., 1994; Xie and

discussions by Srikanth Chary, Gayle Derfus, Veronica Carvalhal,

Wang, 1994a,b). However, since growth rates and nutrient

Jason Goodrick, and Robert Kiss.

consumption rates vary during the course of any givenculture, which have impact on specific substrate uptakerates, an on-line or off-line measurement is needed to either

automatically or manually adjust feed rates. In our work, thecapacitance signal was successfully used as a surrogate of

Arnoux AS, Preziosi-Belloy L, Esteban G, Teissier P, Ghommidh C. 2005.

culture growth, and constant re-calculation of growth rates

Lactic acid bacteria biomass monitoring in highly conductive media bypermittivity measurements. Biotechnol Lett 27(20):1551–1557.

was done automatically to allow for change of feed rates.

Bibila TA, Robinson DK. 1995. In pursuit of the optimal fed-batch process

The asparagine consumption rate, used as an indicator

for monoclonal antibody production. Biotechnol Prog 11(1):1–13.

metabolite for feed rate calculation, was initially derived

Chee Furng Wong D, Tin Kam Wong K, Tang Goh L, Kiat Heng C, Gek Sim

from historical data and then adjusted throughout evolution

Yap M. 2005. Impact of dynamic online fed-batch strategies on

of the feed medium formulations. On the other hand, the

metabolism, productivity and N-glycosylation quality in CHO cellcultures. Biotechnol Bioeng 89(2):164–177.

feedback-based method does not rely on growth or nutrient

Chen W, Graham C, Ciccarelli RB. 1997. Automated fed-batch fermenta-

consumption rate models. Instead, it relies on more frequent

tion with feed-back controls based on dissolved oxygen (DO) and

measurement of the indicator metabolite, for example,

pH for production of DNA vaccines. J Ind Microbiol Biotechnol 18:

glucose, and the subsequent feeding that is designed to bring

the indicator metabolite to a preset control level (Chee

Derfus GE, Abramzon D, Tung M, Chang D, Kiss R, Amanullah A.

2009. Cell culture monitoring via an auto-sampler and an integrated

Furng Wong et al., 2005; Lee et al., 2003; Zhou et al., 1995,

multi-functional off-line analyzer. Biotechnol Prog 26(1):284–

1997). This strategy has been successfully used to control low

levels of glucose and glutamine, but for this work glucose

Dowd JE, Kwok KE, Piret JM. 2001a. Glucose-based optimization of CHO-

was maintained at around 4–5 g/L in order to keep the

cell perfusion cultures. Biotechnol Bioeng 75:252–256.

culture from either over-feeding or under-feeding. Glucose

Dowd JE, Kwok KE, Piret JM. 2001b. Predictive modeling and loose-loop

control for perfusion bioreactors. Biochem Eng J 9:1–9.

as a feed indicator is simple, requires the least prior

Gong X, Li D, Li X, Fang Q, Han X, Wu Y, Yang S, Shen BQ. 2006. Fed-

knowledge and is adaptable to both changes in cell density

batch culture optimization of a growth-associated hybridoma cell

and metabolism.

line in chemically defined protein-free media. Cytotechnology 52(1):

It is also important to note that the overall improvements

on productivity, for example, from 4 g/L of the baseline

Huang YM, Hu W, Rustandi E, Chang K, Yusuf-Makagiansar H, Ryll T.

2010. Maximizing productivity of CHO cell-based fed-batch culture

platform process to 9.1 g/L for the dynamic feeding process,

using chemically defined media conditions and typical manufacturing

is only possible with the optimized feed medium. The

equipment. Biotechnol Prog 26(5):1400–1410.

automatic dynamic feeding method, however, made it

Junker BH, Wang HY. 2006. Bioprocess monitoring and computer control:

possible to evaluate the various feed medium formulations

key roots of the current PAT initiative. Biotechnol Bioeng 95(2):226–

without the need to establish a priori how these different

Kelley B. 2009. Industrialization of mAb production technology: The

feed media should be administered in terms of dose and

bioprocessing industry at a crossroads. MAbs 1(5):443–452.

frequency. Therefore, the combined approach of dynamic

Kim BS, Lee SC, Lee SY, Chang YK, Chang HN. 2004. High cell density fed-

feeding and iterated feed medium optimization has the clear

batch cultivation of Escherichia coli using exponential feeding com-

synergistic benefit. Automation is also a main feature in our

bined with pH-stat. Bioprocess Biosyst Eng 26:147–150.

studies, as many earlier efforts on dynamic feeding had to

Kiviharju K, Salonen K, Moilanen U, Eerikainen T. 2008. Biomass mea-

surement online: The performance of in situ measurements and

rely on manual adjustments based on off-line measurements

software sensors. J Ind Microbiol Biotechnol 35(7):657–665.

(Xie and Wang, 1994a,b, 1996; Xie et al., 1997; Yu et al.,

Krairak S, Yamamura K, Irie R, Nakajima M, Shimizu H, Chim-Anage P,

2011; Zhou et al., 1995, 1997a,b). Advances in automation

Yongsmith B, Shioya S. 2000. Maximizing yellow pigment production

have enabled more advanced feedback control mechanisms

in fed-batch culture of Monascus sp. J Biosci Bioeng 90(4):363–367.

without a concomitant increases in labor. A fully integrated

Kurokawa H, Park YS, Iijima S, Kobayashi T. 1994. Growth characteristics

in fed-batch culture of hybridoma cells with control of glucose and

sampling, data acquisition, and control system has the

glutamine concentrations. Biotechnol Bioeng 44:95–103.

capability of responding to a wide variety of inputs.

Kuwae S, Ohda T, Tamashima H, Miki H, Kobayashi K. 2005. Development

Alternative methods could also be developed for subgroups

of a fed-batch culture process for enhanced production of recombinant

of metabolites that could be broken up into separate feeds

human antithrombin by Chinese hamster ovary cells. J Biosci Bioeng

that vary in predetermined ratios to one another. An

Lee YY, Yap MG, Hu WS, Wong KT. 2003. Low-glutamine fed-batch

expansion in the number of available inputs could further

cultures of 293-HEK serum-free suspension cells for adenovirus pro-

improve feeding algorithms to develop a control system that

duction. Biotechnol Prog 19(2):501–509.

is dependent on inherent cell metabolism. An evolution of

Li J, Wong CL, Vijayasankaran N, Hudson T, Amanullah A. 2012. Feeding

this feeding algorithm could define a platform process that

lactate for CHO cell culture processes: Impact on culture metabolism

adapts to natural variations in cell lines in order to ensure

and performance. Biotechnol Bioeng 109:1173–1186.

Opel CF, Li J, Amanullah A. 2010. Quantitative modeling of viable cell

optimal productivity and quality is reached in the shortest

density, cell size, intracellular conductivity, and membrane capacitance

time possible, translating technological advancements into

in batch and fed-batch CHO processes using dielectric spectroscopy.

high throughput process development.

Biotechnol Prog 26(4):1187–1199.

Biotechnology and Bioengineering, Vol. 110, No. 1, January, 2013

Po¨rtner R, Schwabe JO, Frahm B. 2004. Evaluation of selected control

Xie L, Nyberg G, Gu X, Li H, Mo¨llborn F, Wang DIC. 1997. Gamma-

strategies for fed-batch cultures of a hybridoma cell line. Biotechnol

interferon production and quality in stoichiometric fed-batch cultures

Appl Biochem 40:47–55.

of Chinese hamster ovary (CHO) cells under serum-free conditions.

Sauer PW, Burky JE, Wesson MC, Sternard HD, Qu L. 2000. A high-

Biotechnol Bioeng 56:577–582.

yielding, generic fed-batch cell culture process for production of

Yu M, Hu Z, Pacis E, Vijayasankaran N, Shen A, Li F. 2011. Understanding

recombinant antibodies. Biotechnol Bioeng 67(5):585–597.

the intracellular effect of enhanced nutrient feeding toward high

Teixeira AP, Oliveira R, Alves PM, Carrondo MJ. 2009. Advances in on-line

titer antibody production process. Biotechnol Bioeng 108(5):1078–

monitoring and control of mammalian cell cultures: Supporting the

PAT initiative. Biotechnol Adv 27(6):726–732.

Zhang L, Shen H, Zhang Y. 2004. Fed-batch culture of hybridoma cells in

Wlaschin KF, Hu WS. 2006. Fedbatch culture and dynamic nutrient

serum-free medium using an optimized feeding strategy. J Chemi Tech

feeding. Adv Biochem Eng Biotechnol 101:43–74.

Xie L, Wang DI. 1994a. Fed-batch cultivation of animal cells using different

Zhou W, Hu W-S. 1994. On-line characterization of a hybridoma cell

medium design concepts and feeding strategies. Biotechnol Bioeng

culture process. Biotechnol Bioeng 44:170–177.

Zhou W, Rehm J, Hu WS. 1995. High viable cell concentration fed-batch

Xie L, Wang DI. 1994b. Applications of improved stoichiometric model in

cultures of hybridoma cells through on-line nutrient feeding. Biotech-

medium design and fed-batch cultivation of animal cells in bioreactor.

nol Bioeng 46(6):579–587.

Zhou W, Chen CC, Buckland B, Aunins J. 1997. Fed-batch culture of

Xie L, Wang DI. 1996. High cell density and high monoclonal antibody

recombinant NS0 myeloma cells with high monoclonal antibody

production through medium design and rational control in a bioreac-

production. Biotechnol Bioeng 55(5):783–792.

tor. Biotechnol Bioeng 51:725–729.

Lu et al.: Automated Dynamic Fed-Batch Process and Media Optimization

Biotechnology and Bioengineering

Source: http://www.novabio.us/press/NovaBio_FLEX_CellCulture.pdf

Marilyn Herie, Ph.D., TSI Tim Godden, M.S.S., TSI Joanne Shenfeld, M.S.S. Colleen Kelly, M.S.S., TSI Guide d'information Guide à l'intention des personnes aux prises avec une toxicomanie et de leur famille Marilyn Herie, Ph.D, TSI Tim Godden, M.S.S., TSI Joanne Shenfeld, M.S.S. Colleen Kelly, M.S.S., TSI Un Centre collaborateur de l'Organisation panaméricaine de la santé et de

2015 ADEA ABSTRACT SUBMISSION PREPARATION Oral presentations and E-Poster presentations Selecting Your Program Streams The Program Organising Committee (POC) accepts submissions of abstracts of original contributions on any topic related to the following program streams: 1. Scientific 2. Program Evaluation/Review of Resource Delivery/Quality Improvement Activity 3. Clinical Practice/Case Studies/Service Delivery