Safeline.ee

BW Clip Real Time

2 OR 3 YEAR H S, CO, O , SO SINGLE-GAS DETECTOR

Part Number 50115903-101 OM-EN-BWCRT-A3 BW Clip Real Time Operator Manual

BW Clip Real Time is a portable, single-gas detector manufactured by BW Technologies by

Honeywell (BW). BW Clip Real Time continuously displays the concentration of a specific

gas in the ambient environment, and activates an alarm when concentrations exceed alarm

setpoints. It is your responsibility to respond appropriately to the alarms.

BW Clip Real Time is a member of the GasAlert family of products. It is compatible with IntelliDoX and MicroDock II automatic test and calibration stations, as well as Fleet Manager II software version 4.2 or higher. For more information, visit the product website at www.

honeywellanalytics.com

Safety Information: Read First

1. Substitution of components may impair Intrinsic Safety.

2. BW recommends performing a bump test prior to each day's use to confirm sensor

response and alarm activation by exposing the detector to a concentration of target gas that exceeds the low alarm set point. BW also recommends performing a bump test if the detector has been subjected to physical impact, liquid immersion, an Over Limit alarm event, custody changes, or anytime the detectors performance is in doubt. Calibrate the detector after a failed bump test. Always bump test and calibrate in a fresh air environment.

3. Detectors in hibernation mode are not functional.

with product name

1. Activate the detector before the activation date on the package.

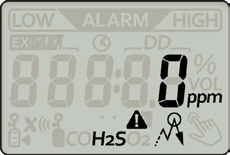

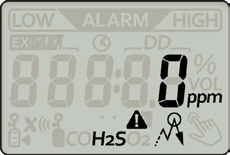

LCD and Symbols

2. This product is a gas detector, not a measurement device.

3. Ensure that the sensor grill is free of dirt, debris, and is not obstructed.

4. Clean the exterior with a soft, damp cloth.

5. Bump test the detector in a normal atmosphere that is free of hazardous gas.

6. For optimal performance, periodically zero the sensor in a normal atmosphere (20.9%

v/v O ) that is free of hazardous gas.

7. Calibrate only in a safe area that is free of hazardous gas in an atmosphere of 20.9%

8. Portable safety gas detectors are life safety devices. Accuracy of ambient gas

Pushbutton prompt. When this symbol is displayed, press and hold

reading(s) is dependent upon factors such as accuracy of the calibration gas standard

the pushbutton until the symbol disappears.

used for calibration and frequency of calibration. BW recommends performing a calibration at least once every 180 days (6 months).

BW Clip Real Time O models only. Oxygen concentration is

measured as percent by volume.

Informations de sécurité – À lire au préalable

BW Clip Real Time H S, CO and SO models only. Toxic gas

concentration is measured in parts per million.

1. Le remplacement d'un composant de l'appareil peut compromettre la sécurité

Low alarm and high alarm. These symbols are displayed when a

intrinsèque du détecteur.

2. Testez périodiquement la réponse du capteur en exposant le détecteur à une

gas concentration that exceeds alarm setpoints is detected.

concentration de gaz supérieure au seuil d'alarme basse. Vérifiez manuellement que les alarmes sonores et visuelles sont activées.

Non-compliance warning. This symbol is displayed when a

3. Détecteurs en mode veille prolongée ne sont pas fonctionnels.

diagnostic or compliance test fails; when the operating life

MISE EN GARDE

countdown reaches 24 hours or less; and for up to 30 days after

1. Activez le détecteur avant la date d'activation sur l'emballage.

operating life expiry. It is also displayed when certain notifications

2. Ce produit est un détecteur de gaz, pas un dispositif de mesure.

are enabled through Fleet Manager II via an IntelliDoX station.

3. Veillez à assurer que la grille du capteur est exempt de saleté, les débris, et ne soit pas

Real-time clock. This symbol is displayed when real-time clock is

4. Nettoyez l'extérieur de l'appareil à l'aide d'un chiffon doux et humide.

enabled through Fleet Manager II via an IntelliDoX station.

5. Veillez à effectuer un test fonctionnel du capteur dans une atmosphère normale qui est

End of operating life warning. This symbol is displayed when the

exempte de gaz dangereux

operating life countdown reaches 24 hours or less.

6. Pour des performances optimales, zéro périodiquement le capteur dans une

atmosphère normale (20,9% v/v O ) qui est exempte de gaz dangereux.

Peak reading. This symbol is displayed when a maximum gas

7. Veillez à effectuer l'étalonnage dans une zone sûre, exempte de gaz dangereux, et dans

exposure event has occurred within the past 24 hours.

une atmosphère contenant 20,9 % v/v O .2

8. Étalonnez le détecteur avant sa première utilisation, puis de manière régulière, en

fonction de l'utilisation et de l'exposition du capteur aux poisons et autres contaminants.

Bump test reminder. If the detector is configured to display a bump

BW recommande d'effectuer un étalonnage au moins une fois tous les 180 jours (6

test reminder, this symbol is displayed when a bump test is due.

BW Clip Real Time Factory Calibration Certificate

indicates a failed bump test.

This instrument was factory inspected, tested and calibrated in accordance with the conditions and requirements of our registered Quality System, Operating Standards and Sales Agreements.

This symbol is displayed when more than 24 hours have elapsed since the last successful zero procedure was performed (O2 models) or indicates a sensor calibration is due (H S, CO and SO

indicates a failed calibration (H S, CO and SO models) or a

failed zero procedure (O models).

Operating life remaining in months (MM) or days (DD).

Part Number 50115903-101 OM-EN-BWCRT-A3 BW Clip Real Time Operator Manual

BW Clip Real Time

2 OR 3 YEAR H S, CO, O , SO SINGLE-GAS DETECTOR

Activate a New Detector

Over-Limit and Under-Limit Alarms

1. Move to a normal atmosphere (20.9% v/v O ) that is free of hazardous gas.

If the gas concentration is beyond the sensor range, OL (over-limit) or

2. Press and hold the pushbutton until a 5 second countdown is displayed, and then

continue to hold until the countdown is complete.

-OL (under-limit) is displayed.

3. When the countdown is complete, the LCD and LEDs turn on and then turn off. The

Audible: 2 beeps per second

detector performs an internal diagnostic test.

Visual: 2 flashes per second

4. When the diagnostic test is successful, the alarm setpoints are displayed and the LEDs

Vibration: 2 vibrations per second

5. The sensor stabilization countdown is displayed. During the countdown, the detector

vibrates continuously for 20 seconds. The time required to stabilize varies depending on sensor type. When the countdown reaches 0, the LEDs flash and the audible alarm

Automatic Zero Reminder for O Models

6. The detector is in normal operating mode when the gas type and concentration are

For O models only, the Automatic Zero Reminder is displayed when

more than 24 hours have elapsed since the last successful zero procedure was performed.

Normal Operating Mode

When the detector is in normal operating mode, the type of gas

detected is permanently displayed. The detected concentration of the

The peak readings symbol is displayed when the sensor is exposed to

gas is displayed until it is disrupted by a pushbutton action, gas alarm,

a gas concentration that exceeds the alarm setpoints. It is no longer

or error event.

displayed when more than 24 hours have passed since the last alarm,

or when a successful bump test is performed via an IntelliDoX or

When the detector is activated for the first time, the operating life

MicroDock II station.

countdown is displayed. Press the pushbutton to display remaining

Non-compliance Symbol and LED Indicators

operating life.

The non-compliance warning symbol is displayed when:

• an internal diagnostic test fails;

90 Days or Less Remaining

• a bump test, calibration or zero procedure fails;

When the operating life countdown reaches 90 days or less before

• a bump test or calibration is due, if enabled;

expiry, the countdown display changes to days. The countdown

• the sensor is exposed to a gas concentration that exceeds alarm setpoints, if enabled.

displays the remaining operating life in days until the countdown

The non-compliance warning symbol is no longer displayed when more than 24 hours have

reaches 24 hours or less before expiry.

passed since the last alarm, or when a successful bump test or calibration is performed

24 Hours or Less Remaining

(manual calibration or via an IntelliDoX or MicroDock II station). The non-compliance

When the operating life countdown reaches 24 hours or less before

warning symbol is permanently displayed when the service-life countdown reaches 24 hours

expiry, the countdown display changes to hours, and the EXPIRY!

or less before expiry, and for up to 30 days after expiry.

warning and non-compliance symbol are displayed.

When Non-compliance after gas exposure is enabled through Fleet Manager II via

an IntelliDoX station, the LEDs flash in an alternating pattern when the non-compliance

End of Operating Life

warning symbol is displayed. When the symbol is first displayed, the top LEDs flash. After

When the operating life countdown ends, the detector deactivates and

30 seconds, the side LEDs flash. After 30 seconds, the pattern repeats until the non-

detector safety functions are disabled. It is possible to retrieve event

compliance warning symbol is no longer displayed.

logs for a limited time after expiry. The EXPIRY! warning and

NOTE: When the detector is bump tested via a MicroDock II station, an abnormal test

non-compliance symbol are displayed for up to 30 days after expiry.

result may occur if non-compliance LEDs are flashing. To suspend the flashing for up to 10

Internal Diagnostic Tests

minutes, press and release the pushbutton. When the flashing stops, insert the detector and

Activated detectors automatically perform one internal diagnostic test every 24 hours. If the

perform the test. If the bump test fails, the LEDs resume flashing.

internal diagnostic test fails, the diagnostic fail-safe begins.

Recall Events and Settings

When the detector is in normal operating mode, press the pushbutton at any time to scroll

1. The EXPIRY! warning and non-compliance symbol are displayed.

through events and settings that are not empty or disabled through Fleet Manager II via an

2. The detector beeps and vibrates.

3. The LEDs flash 2 times per second for 15 seconds.

IntelliDoX station. BW Clip Real Time flashes, vibrates and beeps.

4. OFF or an error code is displayed. The detector is deactivated.

While an event or setting is displayed, press the pushbutton to scroll to the next available

It is possible to retrieve the event logs for a limited time after expiry. If you are unable to

event or setting. If you do not press the pushbutton, or if you have reached the last available

retrieve the event logs, contact BW.

event or setting, the detector returns to normal operation. Events and settings are displayed in this order:

Alarms and Warnings

1. Peak Reading, if available, and when a maximum gas exposure event has occurred

An alarm is initiated when the sensor is exposed to a gas concentration that exceeds alarm

within the past 24 hours.

setpoints. The alarm persists until the alarm gas concentration returns to an acceptable

2. Time of Peak Reading, if Real-time Clock display is enabled.

range. Battery life decreases rapidly when the detector is in alarm condition.

3. Operating Life, the remaining operating life of the detector in months, days or hours.

Low Alarm

4. Low Alarm Setpoint

5. High Alarm Setpoint

Audible: 1 beep per second

6. Real-time Clock, if enabled.

Visual: 1 flash per second

7. Firmware Version

8. Next Bump Due, if enabled.

Vibration: 1 vibration per second

9. Next Calibration Due, if enabled.

High Alarm

10. Hibernation, for 2-year H S and CO models only.

Audible: 2 beeps per second

Visual: 2 flashes per second

Vibration: 2 vibrations per second

Part Number 50115903-101 OM-EN-BWCRT-A3 BW Clip Real Time Operator Manual

Zero the Sensor

Event Logs

Over time and through use, the sensor baseline at zero exposure may drift from the

The detector stores the last 35 events that occurred, including peak readings, bump tests,

manufacturer's baseline. For optimal performance of O models, BW recommends that

calibrations and auto zeros. Each record contains:

you zero the O sensor once every 24 hours or when the Automatic Zero Reminder is

• detector serial number, sensor type and life-remaining;

displayed. For all other models, BW recommends that you zero the sensor periodically.

• total number of events that have occurred;

• event type and duration;• alarm level(s) in ppm or %;

1. Move to a normal atmosphere (20.9% v/v O ) that is free of

• time elapsed since the alarm occurred in days/hours/minutes;

hazardous gas.

2. Press and hold the pushbutton until a 5 second countdown

• duration of the alarm (minutes/seconds).

is displayed, and then continue to hold until the countdown is

Use Fleet Manager II via an IntelliDoX or MicroDock II station to transfer event logs from the

detector to a computer. When logs are transferred via an IntelliDoX station, the most recent

3. When the countdown is complete, the Zero procedure begins and

35 events are transferred. When logs are transferred via a MicroDock II station, the most

ZErO is displayed.

recent 10 events are transferred.

4. When Zero is successful, PASS and then CAL ? is displayed.

Press the pushbutton to calibrate, or wait for the detector to enter

normal operating mode after a 5 second countdown.

Use Fleet Manager II via an IntelliDoX station to enable the following optional settings for

5. If Zero is not successful, the non-compliance LED flashes. FAIL

BW Clip Real Time detectors.

and the non-compliance warning symbol are displayed. Press

Non-compliance After Gas Exposure

the pushbutton to acknowledge the result and return to normal operation. The non-compliance warning symbol is displayed and

When Non-compliance after gas exposure is enabled, the LEDs flash in an alternating

the non-compliance LED flashes. Perform the Zero procedure

pattern when the sensor is exposed to a gas concentration that exceeds alarm setpoints.

again. If the procedure fails again, contact BW.

When the gas exposure is detected, the top LEDs flash. After 30 seconds, the side LEDs

Bump Tests

flash. After 30 seconds, the pattern repeats until more than 24 hours have passed since the last alarm, or when a successful bump test is performed via an IntelliDoX or MicroDock II

When the detector is configured to display a bump test reminder, the bump test symbol is

displayed when a bump test is due. For best results, bump test the detector via an IntelliDoX or MicroDock II station. Bump tests performed via an IntelliDoX or MicroDock II station are

Real-time Clock Display

logged as bump tests. Manual bump tests are logged as unsafe gas concentrations.

When real-time Clock Display is enabled, you can display the current

time by pressing the pushbutton to Recall Events and Settings, and

then continuing to press the pushbutton until the time is displayed.

By default, BW Clip Real Time is configured to use the following calibration gas mixtures:

Time may be displayed in 12-hour or 24-hour clock format.

H S: 20 ppm

CO: 100 ppm

SO : 20 ppm

O : 18.0 % v/v O

You can use Fleet Manager II software via an IntelliDoX station to change a detector's

Hibernation is a factory installed feature that is available for 24-month H S and CO

default calibration gas mixtures. If the detector's default calibration mixtures were changed,

detectors. When Hibernation is activated, the operating life countdown is suspended. Use

use the gas mixture values from Fleet Manager II to calibrate the detector.

Hibernation to deactivate the detector for 7 days or longer, up to a maximum of 12 months.

1. Move to a normal atmosphere (20.9% v/v O ) that is free of hazardous gas.

When Hibernation is activated, all detector safety functions are disabled.

2. Connect the calibration hose to the gas cylinder and to the intake inlet on the calibration

Activate Hibernation via BW Clip Real Time

3. Press and hold the pushbutton until a 5 second countdown

is displayed, and then continue to hold until the countdown is

1. Have ready a BW Clip Hibernation Case. To purchase a Case,

complete. The zero procedure begins and ZErO is displayed.

contact BW or an authorized distributor.

When Zero is successful, PASS is displayed.

2. Move to a normal atmosphere (20.9% v/v O ) that is free of

4. When CAL ? is displayed, press the pushbutton to begin

hazardous gas.

3. Verify that the detector is in normal operating mode.

5. Put the calibration cap on the sensor grill.

4. Press the pushbutton to Recall Events and Settings, and then

6. When GAS ? is displayed, apply calibration gas for two minutes

continue to press the pushbutton until Hib is displayed.

at a recommended flow rate of 500 ml/min. When calibration is

successful, PASS is displayed and the detector returns to normal

operating mode.

5. While Hib is displayed, press the pushbutton until a 5 second countdown is displayed.

If calibration fails, non-compliance warning symbols are displayed. Press the pushbutton to

When the countdown is complete, the 20-second Hibernation counter is displayed.

acknowledge. Repeat calibration. If it fails again, contact BW.

6. While the Hibernation counter is displayed, place the detector into a BW Clip Real

Time Hibernation Case and then close the case firmly. The detector enters Hibernation

mode. All detector safety functions are disabled.

7. To reactivate the detector, open the case and remove the detector.

Activate Hibernation through Fleet Manager II

1. Use Fleet Manager II to activate Hibernation on Insertion via an IntelliDoX station, and

then insert the detector in the configured station. The detector event logs are retrieved,

and the detector enters Hibernation mode. All safety functions are disabled, and the

detector may be removed from the IntelliDoX station.

2. To reactivate the detector, press and hold the pushbutton until a 5 second countdown

is displayed, and then continue to hold until the LCD and LEDs turn on and off. The detector performs a self-diagnostic test. When the test is successful, the type of gas detected and the remaining operating life are displayed. The detector is in normal operating mode.

3. For more information, refer to the operator manuals for the IntelliDoX station and Fleet

Manager II software version 4.2 or higher.

Part Number 50115903-101 OM-EN-BWCRT-A3 BW Clip Real Time Operator Manual

BW Clip Real Time

2 OR 3 YEAR H S, CO, O , SO SINGLE-GAS DETECTOR

About this Publication

Factory Alarm Setpoints

O -20° to +50°C (-4° to +122°F)

Limited Warranty and

This publication is an operator guide for

Low Alarm

High Alarm

SO -30° to +50°C (-22° to +122°F)

Limitation of Liability

BW Clip Real Time portable single-gas

BW Technologies (BW) warrants this

detectors manufactured by BW Technologies

product to be free from defects in material

by Honeywell. It is intended for use with the

O 19.5% v/v O

Operates to -10°C (+14°F)

and workmanship under normal use and

following models:

service for a period of two or three years

• 24- and 36-month H S and CO Detectors

(depending upon detector), beginning on the

5% to 95% relative humidity

• 24-month O detector

Use Fleet Manager II via an Intel iDoX

date of activation. 24-month H S and CO

• 24-month SO detector

station to adjust alarm setpoints. For

detectors are covered for up to an additional

more information, refer to the operator

12 months when hibernation is used, limited

Copyright, Notice, Trademarks

manuals for Fleet Manager II software

≈ 95 dB at 10 cm (3.9 in)

by a total of 24 months of detector operation.

While this information is presented in

version 4.2 and the Intel iDoX automatic

Visual Alarm

This Warranty is valid only if the detector is

good faith and believed to be accurate,

test and calibration station.

activated by the date on the package. This

BW Technologies by Honeywell (BW)

Flashing, wide-angled alarm lens with red warranty extends only to the sale of new and

disclaims the implied warranties of

Ratings and Certifications

LEDs plus alarm LCD readout

unused products to the original buyer.

merchantability and fitness for a particular

The BW Clip Real Time is in conformity with

BW's warranty obligation is limited, at BW's

purpose and makes no express warranties

the following standards:

Liquid crystal display (LCD)

option, to refund of the purchase price, repair,

except as may be stated in its written

UL 913 8th Edition

Sensor Type

or replacement of a defective product that is

agreement with and for its customers.

UL 60079-0:2013,

Electrochemical cells

returned to a BW authorized service center

In no event is BW liable to anyone for any

within the warranty period. In no event shall

indirect, special or consequential damages.

BW's liability hereunder exceed the purchase

The content in this document is subject to

CSA C22.2 No. 157-92:2012,

Lithium, non-replaceable

price actually paid by the buyer for the

CSA C22.2 No. 60079-0:2011,

CSA C22.2 No. 60079-11:2014

Contact Us

EN 60079-0:2012 +A11:2013,

This warranty does not include:

• fuses, disposable batteries or the routine

EN 60079-11:2012

Instant low and instant high

replacement of parts due to the normal

BW Technologies by Honeywell

wear and tear of the product arising from

2840 – 2nd Avenue SE

IEC 60079-0:2011

Calgary AB Canada T2A 7X9

IEC 60079-11:2011

To ensure accurate calibration, BW

• any product which in BW's opinion,

IEC 60079-26:2006

Technologies recommends using a

premium-grade calibration gas approved

has been misused, altered, neglected

ABNT NBR IEC 60079-0:2008

by the National Institute of Standards and

or damaged by accident or abnormal

BW Technologies by Honeywell

ABNT NBR IEC 60079-11:2009

Technology (NIST).

conditions of operation, handling or use; or

405 Barclay Blvd.

ABNT NBR IEC 60079-26:2008

• any damage or defects attributable to

Lincolnshire IL USA 60069

Do not use a gas cylinder beyond its expiry

repair of the product by any person

Classified by UL to both US and

other than an authorized dealer, or the

BW Technologies recommends you calibrate

Canadian Standards as intrinsically safe

installation of unapproved parts on the

the detector at least once every 180 days

BW Technologies by Honeywel

for Class I, Division 1, Group A, B, C, D

depending on use and sensor exposure to

The obligations set forth in this warranty are

and Class I, Zone 0, Group IIC.

poisons and contaminants. Calibrate only in a

safe area that is free of hazardous gas.

1) proper storage, installation, calibration,

Nuffield Industrial Estate

Allowable Calibration Gas Mixtures

use, maintenance and compliance with

Poole Dorset BH17 0RZ United Kingdom

Ex ia IIC T4 Ga IP66/67

H S 5 to 50 ppm

the product manual instructions and any

Tol -free: +44(0)1295 700300

DEMKO 14 ATEX 1356

CO 25 to 250 ppm

other applicable recommendations of BW;

2) the buyer promptly notifying BW of any

SO 5 to 70 ppm

European Conformity

defect and, if required, promptly making

O 5.0 % to 19.0 % v/v O

the product available for correction.

EC Declaration of Conformity

For O detectors, perform the Zero procedure

No goods shall be returned to BW

once every 24 hours or when the Automatic

until receipt by the buyer of shipping

Zero Reminder is displayed.

instructions from BW; and

Ex ia IIC T4 Ga IP66/67

Intended Use

3) the right of BW to require that the buyer

Maximum Operating Life

This product is classified for use in hazardous

provide proof of purchase such as the

original invoice, bill of sale or packing slip

atmospheres that are not more than

to establish that the product is within the

2 years after activation, assuming

warranty period.

2 minutes of alarm time per day.

THE BUYER AGREES THAT THIS

Note: 24-month H S and CO detectors

WARRANTY IS THE BUYER'S SOLE AND

that use hibernation may extend the

This instrument contains a lithium battery. Do

EXCLUSIVE REMEDY AND IS IN LIEU OF

service period of the detector up to an

not mix with the solid waste stream. Spent

ALL OTHER WARRANTIES, EXPRESS

additional year. The service life will end

batteries should be disposed of by a qualified

OR IMPLIED, INCLUDING BUT NOT

once the detector reaches 24 months of

RU C-US.ГБ08.B.01381

recycler or hazardous materials handler.

LIMITED TO ANY IMPLIED WARRANTY OF

actual operation. Hibernation provides a

MERCHANTABILITY OR FITNESS FOR A

maximum service life of 36 months.

PARTICULAR PURPOSE. BW SHALL NOT

Shelf Life

Products may contain materials that are

BE LIABLE FOR ANY SPECIAL, INDIRECT,

3 years after activation, assuming

H S One (1) year before activation

INCIDENTAL OR CONSEQUENTIAL

regulated for transportation under domestic

1 minute of alarm time per day.

CO One (1) year before activation

and international dangerous goods

DAMAGES OR LOSSES, INCLUDING LOSS

regulations. Return product in compliance

OF DATA, WHETHER ARISING FROM

O Six (6) months before activation

with appropriate dangerous goods

BREACH OF WARRANTY OR BASED ON

H S 0 to 100 ppm

S0 One (1) year before activation

regulations. Contact freight carrier for further

CONTRACT, TORT OR RELIANCE OR ANY

CO 0 to 300 ppm

Instrument Weight

OTHER THEORY.

O 0 to 25% v/v O

alligator clip included

Since some countries or states do not allow

SO 0 to 100 ppm

92 grams (3.2 ounces)

limitation of the term of an implied warranty,

Instrument Dimensions

or exclusion or limitation of incidental or

alligator clip included

consequential damages, the limitations and

41 x 50 x 87 mil imeters

exclusions of this warranty may not apply to

(1.6 x 2.0 x 3.4 inches)

every buyer. If any provision of this warranty

is held invalid or unenforceable by a court of

H S -40° to +50°C (-40° to +122°F)

competent jurisdiction, such holding will not

affect the validity or enforceability of any other

CO -30° to +50°C (-22° to +122°F)

Part Number 50115903-101 OM-EN-BWCRT-A3 BW Clip Real Time Operator Manual

Source: http://www.safeline.ee/wp-content/uploads/BW-Clip-RT-Operators-Manual.pdf

Reimbursement Guide - Cardiology Guide for Myocardial Perfusion Imaging including radiopharmaceuticals and related product information 2015 Reimbursement Guide for Myocardial Perfusion Imaging including radiopharmaceuticals and related product information Cardinal Health is the only national network that provides the full range of patient-specific, unit dose, cardiac imaging agents for nuclear medicine which includes:

Mamm Genome (2007) 18:871–879 Novel repeat polymorphisms of the dopaminergicneurotransmitter genes among dogs and wolves Krisztina Hejjas Æ Judit Vas Æ Eniko Kubinyi Æ Maria Sasvari-Szekely ÆAdam Miklosi Æ Zsolt Ronai Received: 21 May 2007 / Accepted: 21 September 2007 / Published online: 30 November 2007Ó Springer Science+Business Media, LLC 2007 Genetic polymorphisms of the neurotransmis-